Custom Rotomolding Solutions for Plastic Products with Precision and Performance

Apr 15,2025

Apr 15,2025

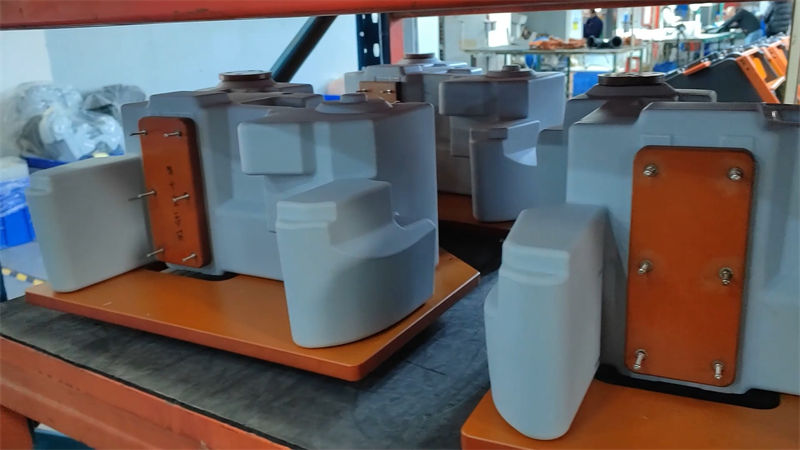

Custom Rotomolding Solutions for Plastic Products with Precision and Performance

At Light Venus, our state-of-the-art rotomolding factory excels in crafting high-end customized plastic rotomolded products meticulously designed to fulfill unique requirements and project specifications. Whether you operate in the agriculture, automotive, material handling, or industrial equipment sectors, our solutions seamlessly blend innovation, precision, and robust durability.

Technical Differentiation

- Our certified engineering team employs a co-creation process utilizing:

- Parametric CAD modeling with FEA validation for dimensional optimization

- Custom tooling design incorporating draft analysis and wall thickness simulations

- Material science expertise in FDA-compliant polyethylene compounds, UV-stabilized resins, and anti-static formulations

Integrated Value Engineering

We implement DFM (Design for Manufacturing) principles to:

1. Incorporate functional elements through strategic bossing and rib design

2. Achieve weight reduction via structural topology optimization

3. Enable unibody construction eliminating secondary assembly

Quality Assurance Protocol

- Multi-stage verification process including:

- In-mold thermal cycle monitoring (±0.5°C precision)

- Post-demolding dimensional verification (laser metrology)

- Performance validation through impact testing (ASTM D256) and load-bearing simulations

Collaborative Partnership Model

- Our client engagement framework features:

- Phase-gated project management with milestone deliverables

- Transparent material traceability documentation

- Full compliance with ISO 9001:2015 and customer-specific certifications

Interested in discovering how we can elevate your business with our custom rotomolding service? Contact us today to discuss your project needs and receive a tailored quote!

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home Light Venus Shipped Over 2000 PCS Custom Rotomolded Speaker Enclosures This Week

Light Venus Shipped Over 2000 PCS Custom Rotomolded Speaker Enclosures This Week  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address