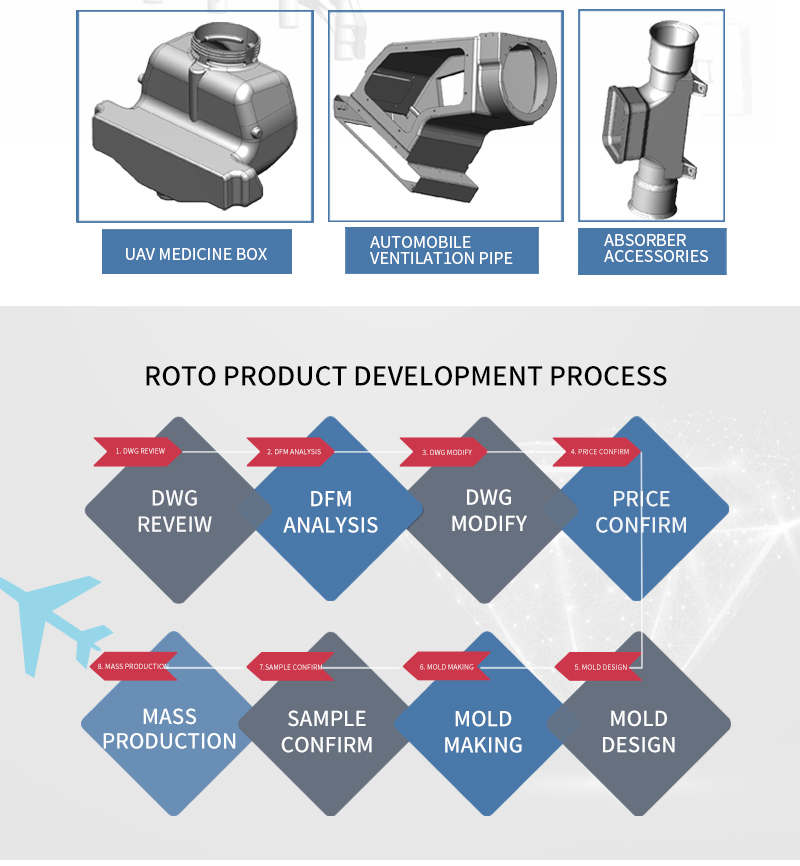

Custom Rotomolding Agriculture Drone Water Spray Tank

Water tank is is roto molded from recyclable polyethylene by means of rotomolding technology. It is designed for agriculture drone to spray measured amounts of pesticides, or fertilizer during crop management.

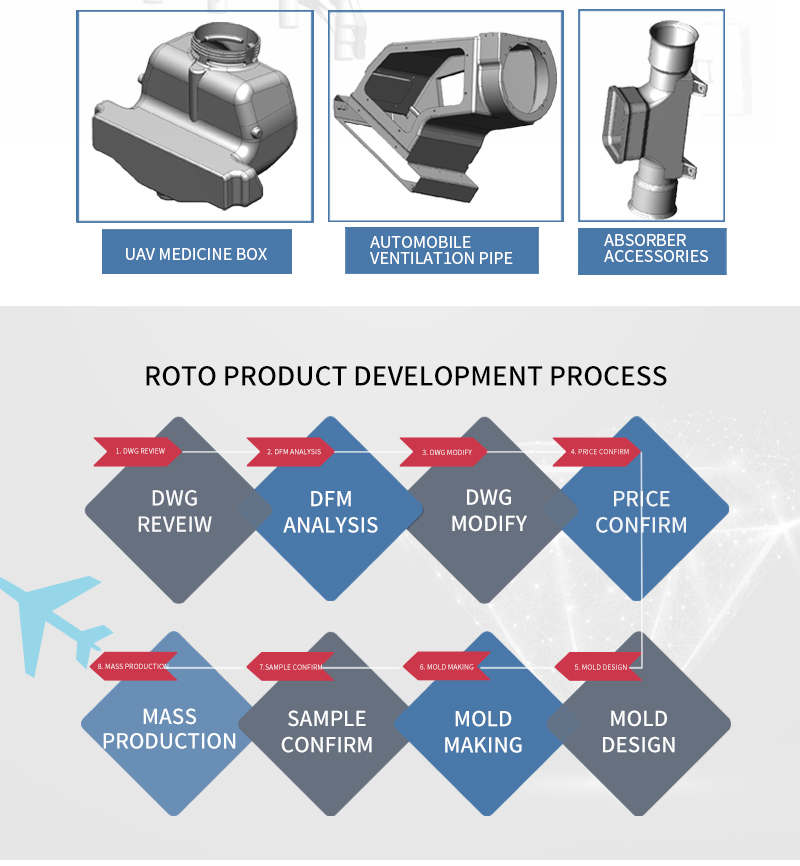

Rotomolding process features

Rotomolding is a thermoplastic forming process to produce hollow, one-piece product . Advantages of rotomolding include design flexibility, durability, low cost tooling and uniform wall thickness. A wide range of sizes and shapes can be molded. Rotomolding also has many options for colors, material selection and textures. Very little material is wasted during the process, and excess material is often re-used, making it economical and environmentally friendly.

Material features

The material of choice for water tank manufacturing is polyethylene because of its excellent properties to meet almost any requirement, whether that is for impact resistance, temperature stability, chemical resistance, colour, UV stability and durability.

Roto-mold water tank features

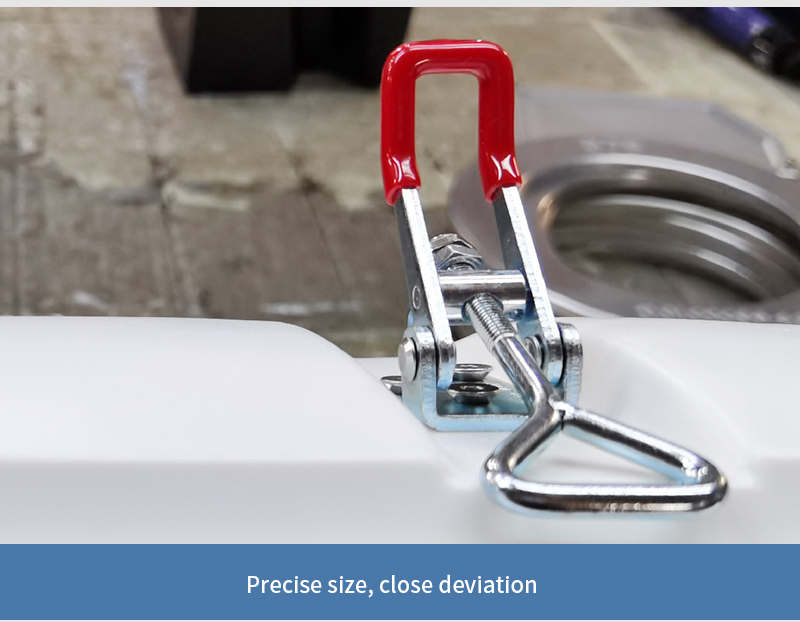

- One-piece product without welded joints.

- Lightweight, easily portable, easy to clean.

- Withstand any type of impact or vibration during use.

- Both the interior and the exterior of the water tanks are smooth, watertight and airtight

- Protection from elements such as corrosion resistant, UV resistant, acid and alkali resistant.

Why choose us

At Light Venus, we make high quality, durable, custom water tanks for customers. We use lean manufacturing principles to efficiently design and produce the rotomolded water tank to the exacting standards.

- Stable production capacity based on the site of 15000㎡

- An excellent teamwork of more than 500 people

- Strong technical support from Roto Molding Association

- ISO9001 certification

- Professional engineering team with skill, knowledge and experiences

- Achieve an efficient development

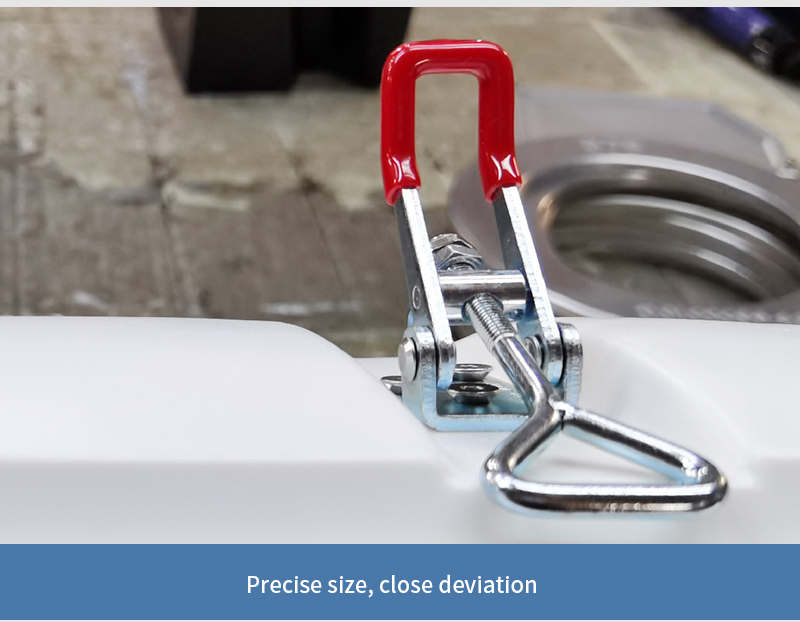

- High-end products with exquisite appearance, precise size control

- 99.9% customer satisfaction

If you want the best custom rotomolded water tanks, send us via email to roto@lightvenus.com to discuss with us for what you need.

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

Related Suggestion

Related Suggestion

Sep 02,2021

Sep 02,2021

Tel

Tel

Email

Email

Address

Address