How Rotomolded Products Quality Issues Are Addressed Quickly at Light Venus

Apr 26,2025

Apr 26,2025

How Rotomolded Products Quality Issues Are Addressed Quickly at Light Venus

As an experienced rotational molding factory, Light Venus has earned a reputation for its unwavering commitment to excellence, particularly when it comes to promptly resolving quality issues with rotomolded products.

The Importance of Quality in Rotomolded Products

Rotational molding, or rotomolding, is a versatile manufacturing process that produces a wide range of plastic products, from large industrial tanks to intricate consumer goods. However, like any manufacturing process, it's not without its challenges. Quality issues can arise due to various factors, including material selection, mold design, temperature control, and processing time. These issues can lead to defects such as thin walls, warping, color inconsistencies, and structural weaknesses, all of which can impact the functionality and durability of the final product.

Light Venus: A Rotational Molding Factory Committed to Quality

At Light Venus, quality is at the heart of everything we do. Our state-of-the-art rotational molding facility is equipped with the latest technology and staffed by a team of highly skilled engineers and technicians who are dedicated to producing the highest quality rotomolded products. We understand that every project is unique, and we work closely with our clients to develop customized solutions that meet their specific requirements.

Advanced Quality Control Systems

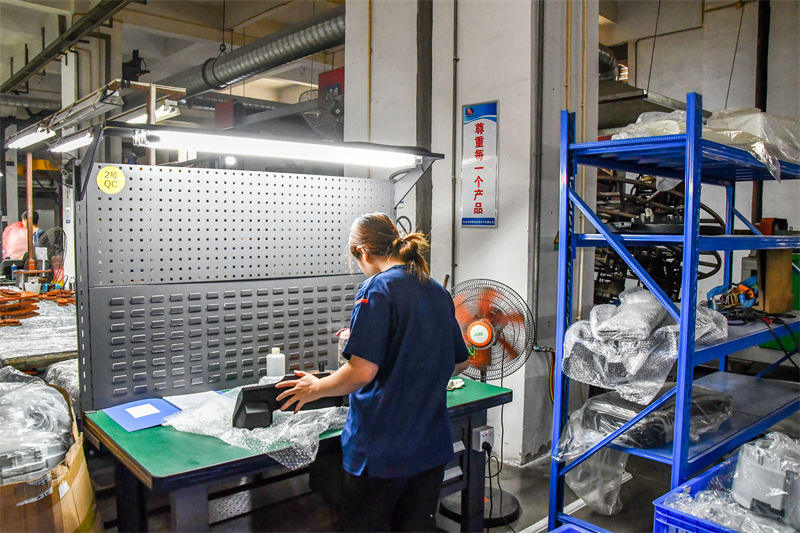

One of the key factors that sets Light Venus apart from other rotational molding factories is our advanced quality control systems. From the moment a project is initiated, our quality control team is involved in every step of the process, ensuring that all materials, processes, and products meet our stringent quality standards.

Material Inspection: We source only the highest quality raw materials from trusted suppliers. Before any material is used in the production process, it undergoes a rigorous inspection to ensure it meets our specifications. This includes checking for impurities, consistency, and performance characteristics.

In-Process Monitoring: During the rotational molding process, our advanced monitoring systems continuously track key parameters such as temperature, rotational speed, and processing time. Any deviations from the set parameters are immediately detected and corrected, preventing potential quality issues from occurring.

Final Product Inspection: Once the rotomolded product is complete, it undergoes a comprehensive final inspection. Our quality control team uses a combination of visual inspection, dimensional measurement, and functional testing to ensure that the product meets all of our quality standards and the client's requirements.

Rapid Response to Quality Issues

Despite our best efforts, quality issues can sometimes arise. At Light Venus, we have a well-defined process for quickly identifying, analyzing, and resolving these issues to minimize downtime and ensure the timely delivery of our products.

Issue Identification: Our quality control team is trained to identify even the smallest quality issues. Whether it's a minor cosmetic defect or a major structural problem, we take every issue seriously and immediately initiate the resolution process.

Root Cause Analysis: Once an issue is identified, our team conducts a thorough root cause analysis to determine the underlying cause. This involves reviewing the production process, analyzing the materials used, and consulting with the production team. By identifying the root cause, we can develop effective solutions to prevent the issue from recurring.

Swift Resolution: Based on the results of the root cause analysis, our team develops and implements a solution as quickly as possible. This may involve adjusting the production process, changing the materials used, or modifying the mold design. We keep our clients informed throughout the process and provide regular updates on the progress of the resolution.

Custom Rotomolded Products Tailored to Your Needs

In addition to our commitment to quality, Light Venus also offers a wide range of custom rotomolded products to meet the diverse needs of our clients. Whether you need a single prototype or a large production run, our team has the expertise and experience to deliver high-quality products on time and within budget.

Design and Development: Our team of experienced designers and engineers works closely with clients to develop custom rotomolded products that meet their specific requirements. We use the latest 3D modeling and simulation software to create detailed designs and ensure the functionality and manufacturability of the product.

Material Selection: We offer a wide range of materials for our rotomolded products, including polyethylene, polypropylene, PVC, and more. Our team can help you select the right material for your application based on factors such as durability, chemical resistance, and temperature tolerance.

Prototyping and Sampling: Before starting production, we offer prototyping and sampling services to ensure that the final product meets your expectations. Our rapid prototyping capabilities allow us to quickly produce a sample of your product for you to review and approve.

Why Choose Light Venus as Your Rotational Molding Factory?

There are many reasons why businesses choose Light Venus as their rotational molding factory of choice. Here are just a few:

Quality Assurance: Our commitment to quality is unwavering. We use the latest technology and the highest quality materials to ensure that our rotomolded products meet the highest standards of quality and durability.

Expertise and Experience: With years of experience in the rotational molding industry, our team has the expertise and knowledge to handle even the most complex projects. We have a proven track record of delivering high-quality products on time and within budget.

Customization: We understand that every project is unique, and we offer a wide range of customization options to meet your specific requirements. From design and material selection to color and finishing, we can create a custom rotomolded product that is tailored to your needs.

Customer Service: At Light Venus, we pride ourselves on providing exceptional customer service. Our team is dedicated to ensuring that our clients are satisfied with every aspect of our products and services. We are always available to answer your questions, provide support, and address any concerns you may have.

With our strict quality control systems, rapid response to quality issues, and commitment to delivering high-quality, custom rotomolded products, Light Venus become a trusted partner for businesses seeking reliable and cost-effective manufacturing solutions. Contact us today to learn more about how we can help you with your next rotomolded product project

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home Light Venus Shipped Over 2000 PCS Custom Rotomolded Speaker Enclosures This Week

Light Venus Shipped Over 2000 PCS Custom Rotomolded Speaker Enclosures This Week  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address