Light Venus Annually Produces Millions of Polyethylene Plastic Ball Lamp Shade with Roto Molding

May 06,2024

May 06,2024

Light Venus Annually Produces Millions of Polyethylene Plastic Ball Lamp Shade with Roto Molding

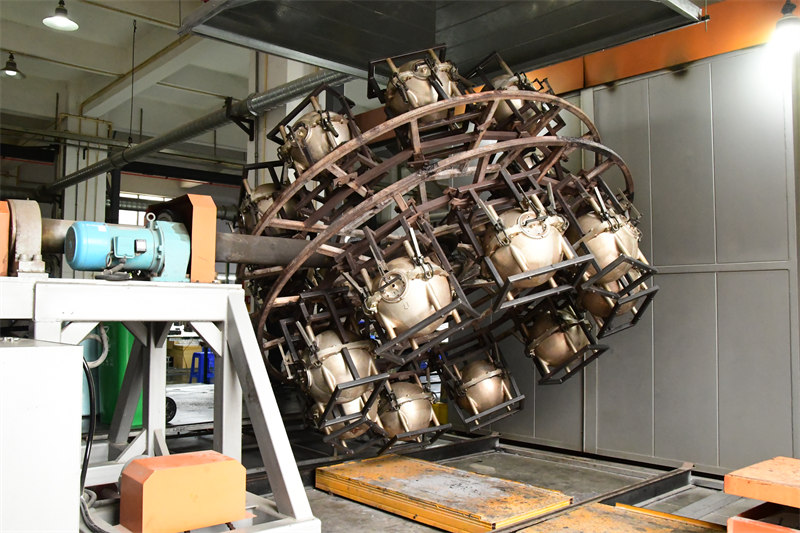

Light Venus produces millions of plastic ball lamp shades annually, each meticulously crafted from weather-resistant, transparent polyethylene using advanced rotational molding techniques. These premium plastic spherical lampshades are engineered for durability, functionality, and aesthetic appeal.

The Rotational Molding Process

Rotational molding is a precision manufacturing method employed to create plastic products with a hollow, consistent shape. It entails heating a plastic material within a sealed mold, which is then rotated to ensure uniform material distribution. As the material cools and hardens, it assumes the exact form of the mold. This method is particularly ideal for manufacturing seamless, uniform, and intricately designed objects such as plastic lampshades.

Advantages of Rotational Molding

1. Uniform Thickness: The rotational molding process guarantees a consistent thickness across the plastic ball lampshades, leading to an even distribution of light and the elimination of dark spots.

2. Seamless Design: The seamless construction of rotationally molded lampshades eliminates the need for additional joints or seams, enhancing their strength, durability, and resistance to breakage.

3. Customization: The versatility of rotational molding allows for the production of lampshades in a multitude of designs, sizes, and colors to suit various aesthetic preferences and requirements.

4. Cost-Effectiveness: The rotational molding process is energy-efficient and minimizes material waste, making it a cost-effective approach for manufacturing plastic lampshades

The Advantage of Polyethylene

Engineered to withstand a spectrum of challenging weather conditions, these plastic ball lampshades are fabricated from lightweight, eco-friendly polyethylene, a resilient plastic known for its superior shock and chemical resistance.

The Advantage of Partnering with Light Venus:

As a seasoned custom roto molding manufacturer with ISO 9001 accreditation, Light Venus is dedicated to providing comprehensive, bespoke solutions for plastic spherical lampshades. Our facility in Zhongshan covers an area of 15,000 square meters and is home to over 500 dedicated professionals. Our team of experienced designers and engineers is poised to work closely with clients to create unique, custom-designed plastic ball lampshades that perfectly capture their vision and requirements. Please free the most welcome to contact us to learn more about our custom roto molding capabilities.

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home Light Venus has Invested Advanced CNC Equipment to Assure the Precision of Rotomolded Products

Light Venus has Invested Advanced CNC Equipment to Assure the Precision of Rotomolded Products  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address