Light Venus Implements Mold Trial for Custom Rotomolded Products

Apr 02,2024

Apr 02,2024

Light Venus Implements Mold Trial for Custom Rotomolded Products

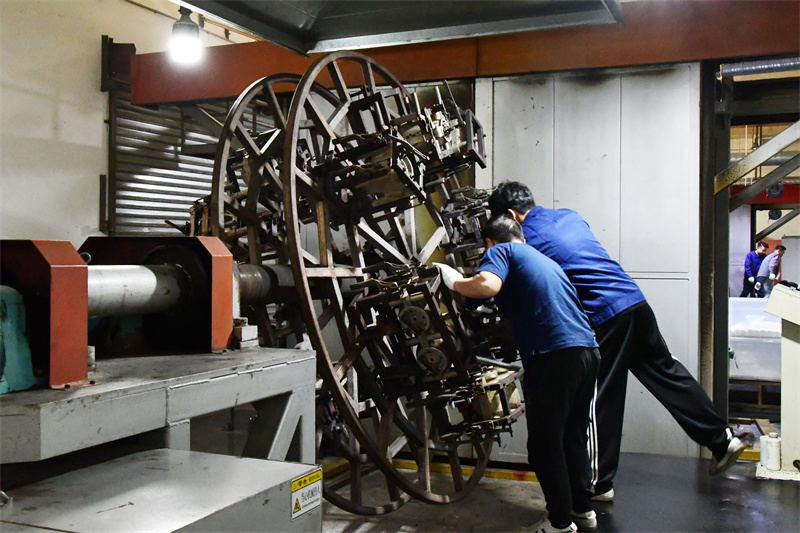

Light Venus is a dedicated provider of custom rotomolding services, committed to delivering high-quality, durable, and functional rotomolded products. To ensure the desired product quality and functionality, we implement a mold trial process, which is a crucial step in the custom rotomolding process.

1. Product Design Perfection:

Light Venus understands the importance of a perfect product design. Through mold trial, they can visualize and test the product design in a tangible form, ensuring that the final product meets the specified dimensions, wall thickness, and desired aesthetics. This enables designers to refine the design and make necessary adjustments before moving to full-scale production.

2. Material Flow and Distribution Analysis:

Mold trial allows Light Venus to analyze the material flow and distribution within the mold. This helps in identifying potential issues, such as material buildup or thinning in specific areas, which may affect the quality of the final product. By testing the mold, Light Venus can make necessary design adjustments to achieve uniform wall thickness and optimal material distribution.

3. Mold Design and Construction Evaluation:

Light Venus utilizes mold trial to evaluate the mold design and construction. This helps in identifying any potential challenges in the molding process, such as difficult demolding or warping issues. By testing the mold, Light Venus can refine the mold design, incorporating features like draft angles, parting lines, and cooling systems to facilitate an efficient production process.

4. Process Optimization:

Light Venus conducts mold trial to optimize the rotational molding process parameters. Factors such as oven temperature, rotation speed, and cooling time can be fine-tuned based on the results from the mold trial. This helps in achieving the desired product quality and reducing production time.

5. Cost and Time Savings:

Light Venus recognizes the importance of cost and time savings in the custom rotomolding process. By conducting a mold trial before the full-scale production mold, Light Venus can identify and address potential design or process issues early in the development stage. This prevents expensive modifications or corrections during the production phase, saving both time and resources.

6. Customer Approval:

Light Venus implements mold trial to obtain customer approval before proceeding with the full-scale production mold. Customers can evaluate the product's design, dimensions, and aesthetics, ensuring that the final product meets their expectations. This customer approval process helps in avoiding costly design changes later in the production cycle.

By investing in mold trial, Light Venus can identify potential issues early in the development stage, saving both time and resources. The use of mold trial contributes to the overall success of the custom rotomolding process and results in high-quality, durable, and appealing custom rotomolded products. Discover our custom rotomolding capability and contact us to discuss your custom rotomolding project.

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home Light Venus Produces Millions of Rotomolded Plastic Lampshade Annually

Light Venus Produces Millions of Rotomolded Plastic Lampshade Annually  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address