Light Venus Provides Custom Precise Rotational Molding Tooling Making Service

Aug 21,2022

Aug 21,2022

Light Venus Provides Custom Precise Rotational Molding Tooling Making Service

Tooling or molds are important for any plastics molding process. Once a design for a rotomolded product is completed, the next process of turning that design into a mold begins. Tooling making or mold fabrication for rotational molding is an important routine task. The quality of the rotational molding tooling manufactured will have a direct correlation on the quality of the parts and components being produced, therefore the experience, accuracy and knowledge of the team that build the rotational molding tooling should be evaluated.

As a custom rotational molding manufacturer with over 500 employees and over 20 years in this industry, we have a wealth of experience and knowledge to make any unique and complicated tooling for rotational molding process. Light Venus tooling program can save both money and time by developing precise molds, which is why we’re such a popular factory of custom rotational molding services.

Highly precise rotational molding tooling

The most important thing to consider with all types of molding is the quality of the mold. There is no substitute for an excellent mold. We can give the guidance on the type of mold best for the application as required, and the plastic material most suitable for the product. Light Venus can provide fabricated aluminum and steel molds, cast aluminum and CNC machined molds with precision. Prior to the start of the tooling, we build a team with experience and knowledge to have a thorough product design review, making sure we completely understand the requirements. Our first mold trial successful rate is over 96%

Cost saving and fast delivery

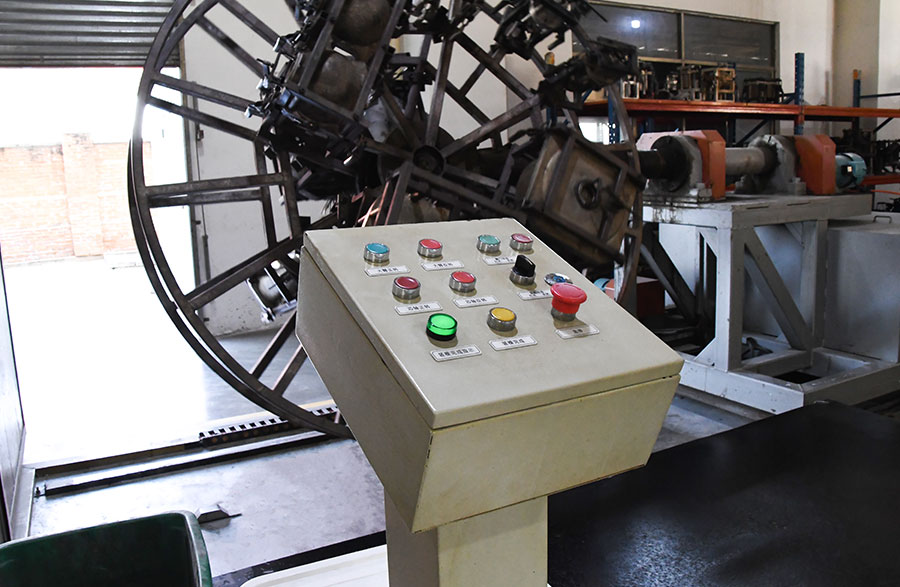

Tooling cost can be one of the key factors in selecting the type of rotational molding tooling. Our in-house machine shop facilities have a wide range of metalworking equipment to handle most needs, which helps expedite the time and save the cost for customer.

Detail oriented

Beside the price, we also have to look aesthetics and function to decide on the right mold for the product. A number of specifics need to takin into consider. Major factors to consider in designing a rotational mold are heat transfer of the material, where parting lines are located, where to vent the part, how the mold is clamped, how the mold is mounted for rotation, and how many parts the mold will make. how the part is removed from the mold, shrinkage factors and more.

Rotational molding tooling maintenance and modification

If you need mold modifications later, we will respond quickly and cost-consciously. Tool maintenance is essential during long run production cycles to keep molds in operation. This includes welding, filling and grinding cracks or scratches in molds, repairing the fasteners to ensure a positive seal or to the frame structure. Tooling modifications include retexturing the interior surface often with shot blast; adding text, logos or graphics by adding to or removing metal to make a recessed or elevated mark

During our many years in business, we’ve designed and created a diverse range of rotomolded products, we’ve worked with clients from different industries, Interested in our custom rotational molding services? Send email to roto@lightvenus.com contact our design and production team.

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home Quality Custom Rotational Molding Service of Agriculture Drone Water Tank at Light Venus

Quality Custom Rotational Molding Service of Agriculture Drone Water Tank at Light Venus  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address