What are the Factors Affecting the Appearance of Rotomolded Rroducts?

Jan 28,2024

Jan 28,2024

22

22

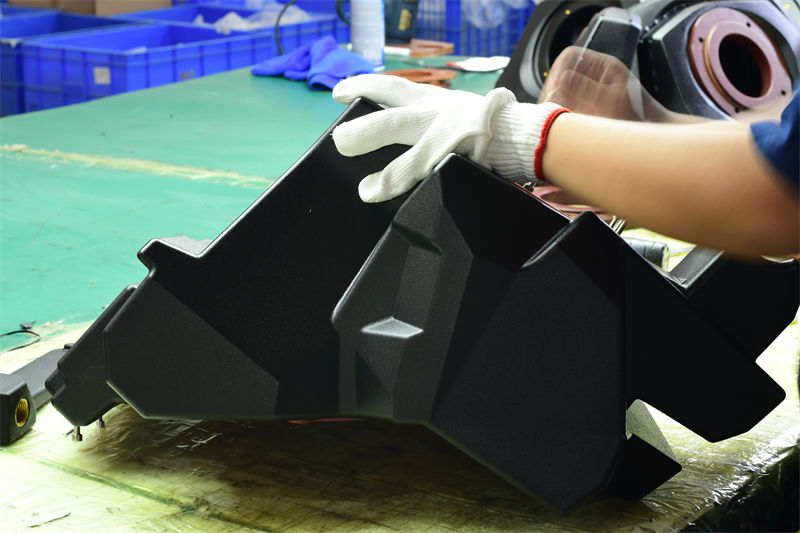

What are the Factors Affecting the Appearance of Rotomolded Products?

The appearance quality of rotational molding products is crucial for their aesthetics and functionality. Below are the main factors that influence the appearance quality of rotomolded products.

1. Material Selection

The choice of plastic material used in rotational molding significantly affects the appearance quality of the final product. Different polymers have varying properties, such as gloss, color, and surface finish. Polymers like polyethylene and polypropylene are commonly used in rotomolding due to their excellent impact resistance and durability. However, the selection of the appropriate material is essential to achieve the desired aesthetic qualities.

2. Mold Design and Construction

The design and construction of the mold play a crucial role in determining the appearance quality of rotational molding products. A well-designed mold ensures uniform thickness and minimal defects in the final product. Features such as smooth surfaces, proper draft angles, and precise dimensions contribute to a high-quality finish. Additionally, the use of high-quality steel and precision machining ensures a flawless mold surface, which is essential for achieving a smooth and blemish-free product appearance.

3. Processing Parameters

Several processing parameters influence the appearance quality of rotomolded products. These include oven temperature, cooling time, and rotation speed. Controlling these parameters is crucial to achieve consistent and high-quality results. Insufficient heating or cooling can lead to uneven material distribution, resulting in surface defects and poor appearance. Conversely, excessive heating or cooling may cause warping or dimensional instability, affecting the overall look of the product.

4. Colorant and Additives

Colorants and additives are often used in rotational molding to enhance the appearance of the final product. However, their improper selection or incorporation can negatively impact the product's aesthetic quality. Some colorants may cause color variations or fading, while certain additives can affect the gloss and transparency of the plastic. It is essential to choose compatible colorants and additives and ensure proper dispersion to achieve a uniform and attractive appearance.

5. Surface Finish

The surface finish of rotational molding products significantly influences their visual appeal. Techniques such as sanding, polishing, and painting can be employed to enhance the product's appearance. These processes help to eliminate surface imperfections, improve gloss, and provide a smooth and aesthetically pleasing finish. Proper surface treatment not only enhances the product's appearance but also improves its durability and resistance to environmental factors.

The appearance quality of rotational molding products is influenced by various factors, including material selection, mold design and construction, processing parameters, colorant and additive choices, and surface finish. Being a custom rotational molding manufacturer, Light Venus carefully considers those factors and implement appropriate techniques in order to produce rotomolded products with excellent aesthetic qualities that meet customer expectations and market demands. Please feel free to contact us to learn more about our custom rotational molding capabilities.

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home How Rotomolding Factory Can Prevent Rotomolded Products from Deformation?

How Rotomolding Factory Can Prevent Rotomolded Products from Deformation?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address