The Demolding Procedure in Rotational Molding Process

May 29,2024

May 29,2024

The Demolding Procedure in Rotational Molding Process

The demolding process in rotational molding, also known as de-molding or unloading, is a critical step that involves removing the finished product from the mold after the cooling phase. Here's a detailed overview of the demolding process in rotational molding:

1 Cooling

After the plastic material has been melted and molded in the rotational mold, the mold needs to be cooled down to solidify the plastic. This is typically done by using water or air cooling systems. The cooling process is crucial as it ensures that the molded product is firm and can be safely removed from the mold without deformation or damage.

2. Opening the Mold

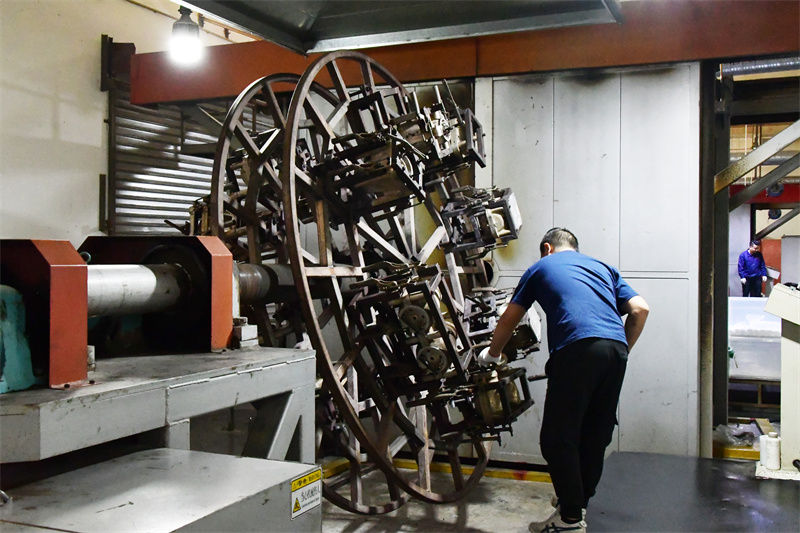

Once the molded product has solidified, the next step is to open the mold. This is usually done by opening two halves of the mold or removing a removable core. The purpose of this step is to expose the molded product and prepare it for demolding.

3. Knocking Out the Molded Product

In this step, the molded product is carefully knocked out from the mold. This can be done using various methods, such as manually pulling the product out or using mechanical devices like extractors or pushers. The goal is to remove the product from the mold without causing any damage to its surface or structure.

4. Post-Demolding Operations

After the molded product has been knocked out, it may require some post-processing to ensure its quality and functionality. This can include trimming off any excess material, deburring, polishing, or applying surface treatments. These steps are essential to achieve the desired final product specifications.

5. Cleaning the Mold

Once the molded product has been demolded and post-processed, the mold needs to be cleaned. This involves removing any remaining plastic material, dust, or debris from the mold's surface. Cleaning the mold is crucial to ensure that the next molding cycle is performed without any interference or defects.

6. Inspection and Quality Control

The demolded product is inspected for quality, checking for dimensions, surface finish, and any defects. This step is crucial for maintaining rotomolded product consistency and quality.

7. Cycle Repetition

Once the product is removed, and the mold is cleaned and inspected, the rotational molding machine can start a new cycle, beginning with loading the mold and adding the plastic powder.

Understanding and mastering the demolding process will contribute to the success and efficiency of rotational molding operations in various industries.

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home How to Optimize the Demolding Stage in Rotational Molding Process

How to Optimize the Demolding Stage in Rotational Molding Process  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address