How Does the Durability of Rotomolded White Polyethylene Plastic Globe Lampshade

Apr 08,2025

Apr 08,2025

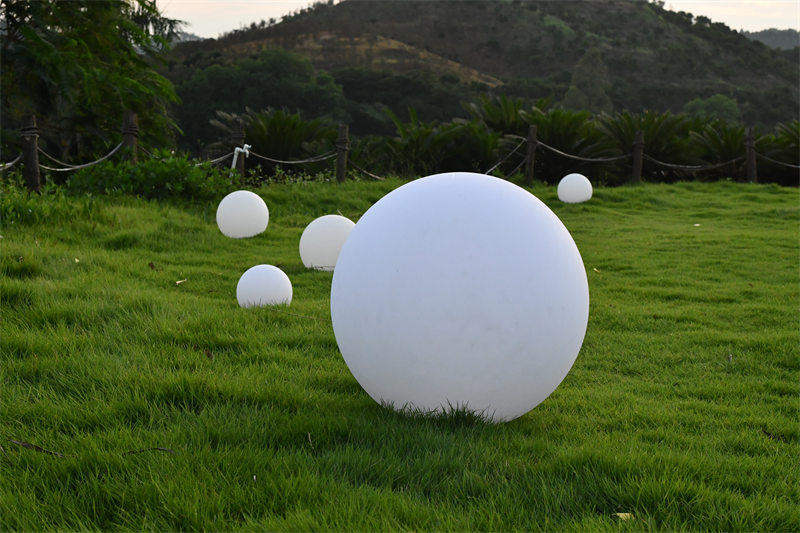

How Does the Durability of Rotomolded White Polyethylene Plastic Globe Lampshade?

Rotational molding, or rotomolding, is a manufacturing process that creates hollow, seamless products. This technique is particularly advantageous for producing plastic lampshades, offering durability and design flexibility.

Manufacturing Process

Rotomolding is a process where a plastic resin is heated and rotated within a mold to create a hollow, seamless product. This method is particularly advantageous for producing lampshades like the white plastic globe, as it allows for even wall thickness and strong, stress-free corners.

Material Matters

The white plastic used in these lampshades is typically a high-density polyethylene (HDPE), known for its robustness and resistance to impact. HDPE is also resistant to UV rays, which means the lampshade is less likely to yellow or degrade when exposed to sunlight over time.

Impact Resistance

One of the standout features of rotomolded lampshades is their exceptional impact resistance. The seamless construction and the flexibility of HDPE mean that these lampshades can withstand bumps and knocks without cracking or breaking. This makes them an ideal choice for high-traffic areas or homes with children and pets.

Weather Resistance

For outdoor lighting, durability against the elements is crucial. Rotomolded white plastic globe lampshades excel in this regard. Their resistance to moisture and temperature fluctuations ensures that they remain intact and functional through rain, snow, and heat. The material's inherent UV resistance also means that the color remains vibrant and untainted by the sun's rays.

Chemical Resistance

Another factor contributing to the durability of rotomolded white plastic globe lampshades is their chemical resistance. The plastic used in the rotational molding process is not easily affected by common chemicals. This means that in environments where there may be exposure to cleaning agents, moisture - related chemicals, or other substances, the lampshade will not corrode or deteriorate. For example, in commercial settings such as hotels or restaurants where regular cleaning is required, these lampshades can maintain their integrity over time.

Longevity and Maintenance

The longevity of rotomolded lampshades is significantly enhanced by their low maintenance requirements. The smooth, non-porous surface of HDPE makes it easy to clean with a simple wipe down. This ease of maintenance not only preserves the lampshade's appearance but also contributes to its long-term durability.

Whether for indoor or outdoor applications, these rotomolded plastic lampshades provide long-term value and performance.

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home How to Choose the Right Cooling Method for Rotomolded Products

How to Choose the Right Cooling Method for Rotomolded Products  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address