What are the Advantages of Sheet Metal Molds Used in the Rotational Molding Process

May 13,2024

May 13,2024

What are the Advantages of Sheet Metal Molds Used in the Rotational Molding Process?

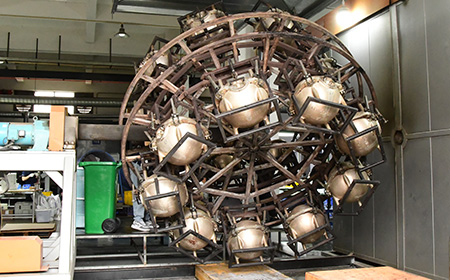

Rotational molding is a process used to manufacture plastic products by heating a mold in a rotational molding machine. The mold is rotated around two axes, which allows the plastic material to flow and cure evenly across the mold's surface, creating a hollow, seamless product. Sheet metal molds are one type of mold used in rotational molding, and they offer several advantages over other types of molds:

1. Cost-Effectiveness

Sheet metal molds are generally less expensive to manufacture than other types of molds, such as aluminum or steel molds. This makes them a more affordable option for businesses, especially for small-scale production or when creating multiple product designs.

2. Easy Design Changes

Sheet metal molds are relatively easy to modify or repair, which allows for quick changes to the product design. This flexibility is particularly useful for businesses that need to make frequent design iterations or produce custom products.

3. Lightweight

Sheet metal molds are lighter in weight than other types of molds, which makes them easier to handle and transport. This can also reduce the energy requirements of the rotational molding machine, as less force is needed to rotate the mold.

4. Good Heat Transfer

Sheet metal molds have good thermal conductivity, which allows for efficient heating and cooling during the rotational molding process. This helps to ensure consistent and uniform plastic cure, resulting in high-quality finished products.

5. Ability to Achieve Complex Shapes

Sheet metal molds can be easily fabricated into complex shapes and geometries, allowing for the production of intricate plastic products that may be difficult or impossible to create with other types of molds.

6. Corrosion Resistance

Sheet metal molds can be coated with materials that provide corrosion resistance, which is particularly important for rotational molding applications involving plastic materials that may be sensitive to corrosive substances.

7. Smooth Surface Finish

Sheet metal molds can be polished to provide a high-quality surface finish, which is beneficial for products that require a cosmetically appealing surface.

8. Faster Cycle Times

Due to their superior heat transfer properties, sheet metal molds allow for faster cycle times compared to other types of molds. This results in increased productivity and reduced downtime during production.

9. Compatibility with automation

Many sheet metal molds are designed to be compatible with automated systems, such as robotic loading and unloading, which can further improve production efficiency and reduce labor costs.

10. Long Lifespan

With proper maintenance and care, sheet metal molds can have a long lifespan, even in the demanding environment of a rotational molding machine. This helps to reduce the overall cost of mold ownership over time.

Overall, sheet metal molds offer a combination of affordability, flexibility, and performance that makes them a popular choice for rotational molding applications across various industries.

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home What Types of Rotational Molding Products are Suitable to Use Sheet Metal Mold

What Types of Rotational Molding Products are Suitable to Use Sheet Metal Mold  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address