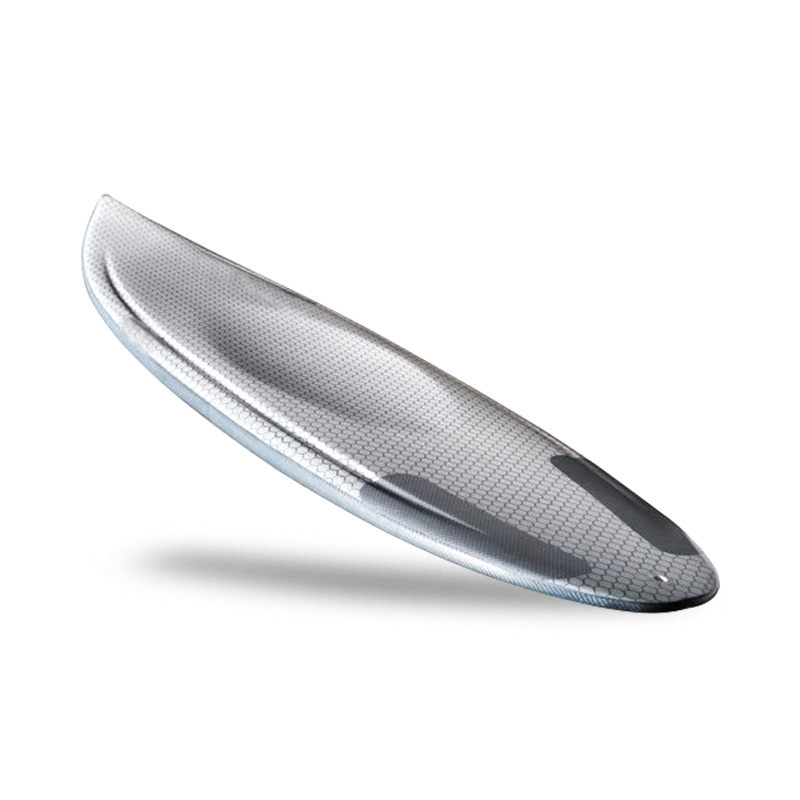

Custom Made Rotationally Molded Durable Electric Surfboards Blanks

Surfboards blanks can be made of polyurethane (PU) foam, fiberglass, epoxy, carbon fiber, polyethylene, and balsa wood. Surfboard made of polyethylene resin as a one-piece product especially by unique rotational moulding process has highest quality standard and a wide range of benefits.

Material key features

Polyethylene is a type of lightweight and 100% recycled ecological resin. The characteristics meet almost any requirement, whether that is for impact resistance, temperature stability, chemical resistance, color, UV stability and durability.

Manufacturing process key features

Rotational moulding, also rotomolding, is known as an extremely versatile, relatively cost-effective method of producing hollow plastic items. The process is ideal for the manufacture of simple or complex shapes. A wide range of surfboard colors and visual appealing designs can be achieved by this process, from long surfboards to short surfboards, fish to fun size, clean outline to aesthetic contours. The design potentials are almost endless. The manufacturing process can also include EPS foam core that ensures their boards are tough enough to surf with waves of different shapes and sizes. Inserts,undercuts, graphics, texture, foam filling and more can be easily molded in to eliminates the need for secondary tooling, or assembly. The rotomoulded surfboards are airtight to protect the inner electronic components.

Why choose us

With 25 years experience in rotational moulding and well controlled production line, Light Venus provides custom surfboards shells by using the high quality plastic and ensure to meet the exact specifications. Length, width, thickness, rails, stringer, tail, and fin setup, color and more can be highly customized. Our manufacturing process is ISO 9001 certified.

Get conversation started on your needs for custom made electric surfboards shells by using the online form, or send us a message.

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

Related Suggestion

Related Suggestion

Sep 02,2021

Sep 02,2021

Tel

Tel

Email

Email

Address

Address