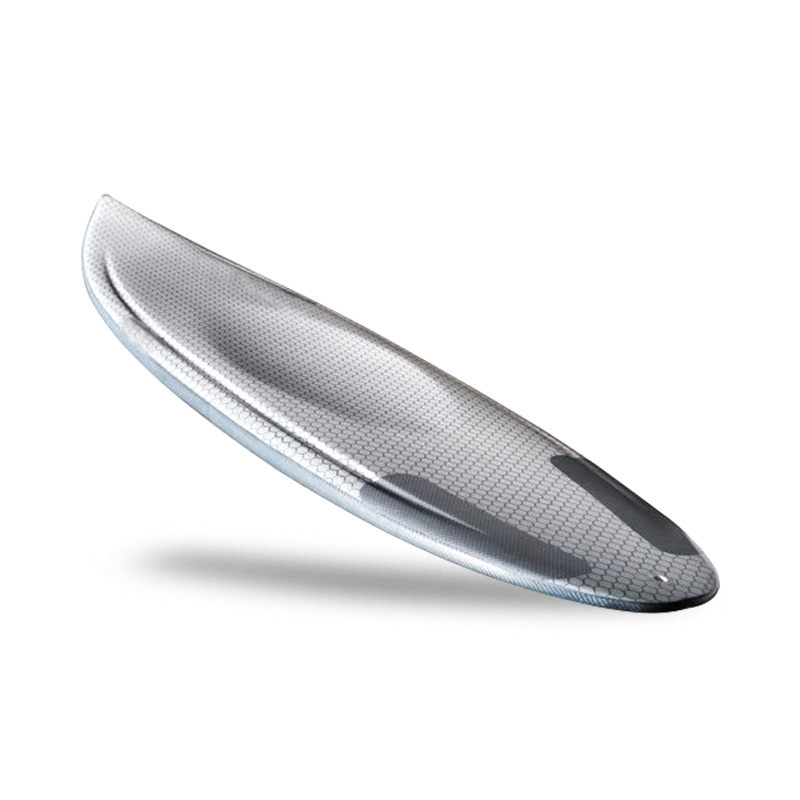

Custom Polyethylene Rotomolding Sturdy Electric Surfboards Blanks

Rotomolding process can produce light and maneuverable electric surfbaords blanks with polyethylene at relative low cost. They are stable and easy buoyant, gaining enthusiasts.

Features and benefit of polyethylene

- Respect to the environment. Polyethylene is 100% recyclable

- Excellent chemical resistance, high stiffness, impact resistance

- UV stability with addition of pigment or UV stabilizer

- Different densities available to suit the application, LDPE, MDPE, LLDPE, HDPE

Features and benefit of rotomolding

- Rotomolding, rotational molding, or rotocasting is a production process to form hollow parts of unlimited size

- Relatively low molds and tooling costs

- One-piece construction that is virtually stress free and airtight

- Lightweight and resilient products with excellent load-bearing properties

- Uniform wall thickness and size can be easily controlled

- Variety of finishes and color can be molded-in color for easy maintenance and long-lasting appearance

- Molded inserts for the mounting of electrical components and PCBs

- Molded-in scratch-proof graphics

- Can produce multi-layer moldings, which can be hollow or foam-filled

- A wide range of other customization

Custom built service from Light Venus

Light Venus crafts surfboards blanks by using the highest quality polyethylene. Designs, colors, sizes, and more are customizable through our excelsior rotomolding process.

- Stable production capabilities based on the site of 15000㎡

- An excellent teamwork of more than 500 people

- Strong technical support from Roto Molding Association

- A wealth of experience, knowledge and skills

- Achieve an efficient development, exquisite appearance, precise size control

- 99.9% customer satisfaction

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

Related Suggestion

Related Suggestion

Sep 02,2021

Sep 02,2021

Tel

Tel

Email

Email

Address

Address