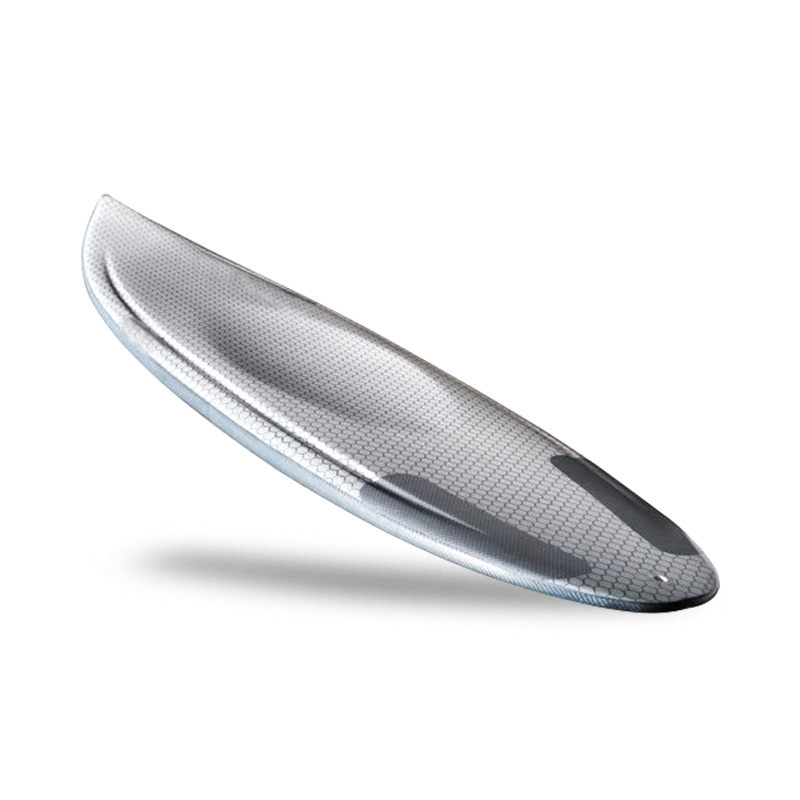

Custom Roto Moulding Formed Electric Surfboard

About the material and manufacturing process

These electric surfboards are made from Eco friendly high density polyethylene of high performance through the roto moulding process. They are lightweight and durable. HDPE plastic has excellent chemical resistance, high stiffness, impact resistance, and also can have UV stability with addition of pigment or UV stabilizer. Roto moulding process is a versatile process that can make a variety of innovative product with high quality of high tensile strength, uniform wall thickness and seamless construction, while the tooling cost is relatively inexpensive

The advantages to work with us

With well established roto moulding production facillity, Light Venus can craft rotomoulded electric surfboards blanks. The length, width, thickness, rails, stringer, tail, and fin setup,colors, textures, and more can be highly customized.

- Stable production capacity based on the site of 15000㎡

- An excellent teamwork of more than 500 people

- Strong technical support from Roto Molding Association

- ISO9001 certification

- Professional engineering team with rich knowledge and experiences

- Achieve an efficient development, exquisite appearance, precise size control

- 99.9% customer satisfaction

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

Related Suggestion

Related Suggestion

Sep 02,2021

Sep 02,2021

Tel

Tel

Email

Email

Address

Address