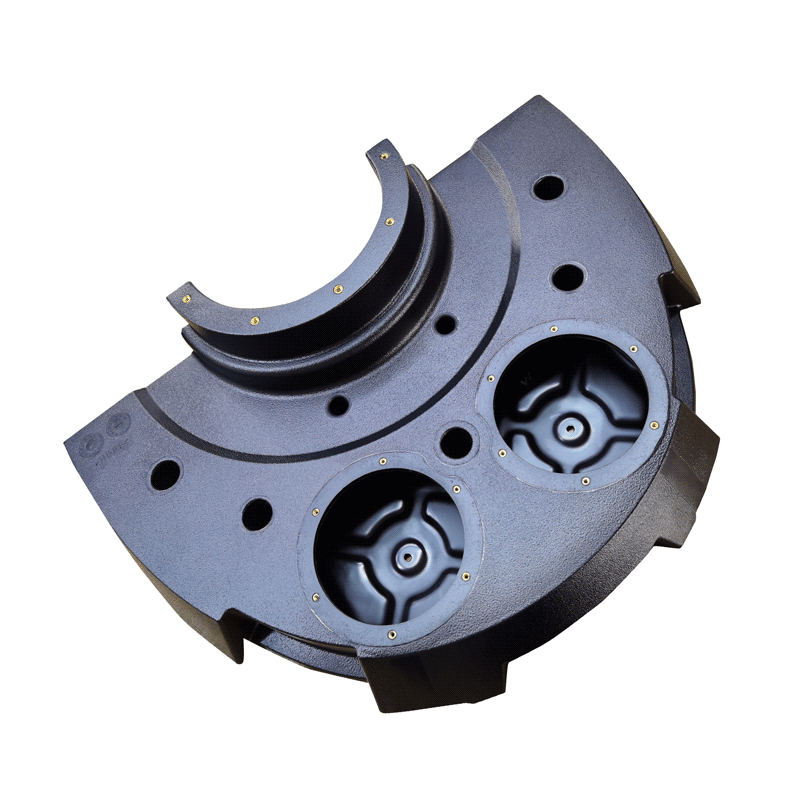

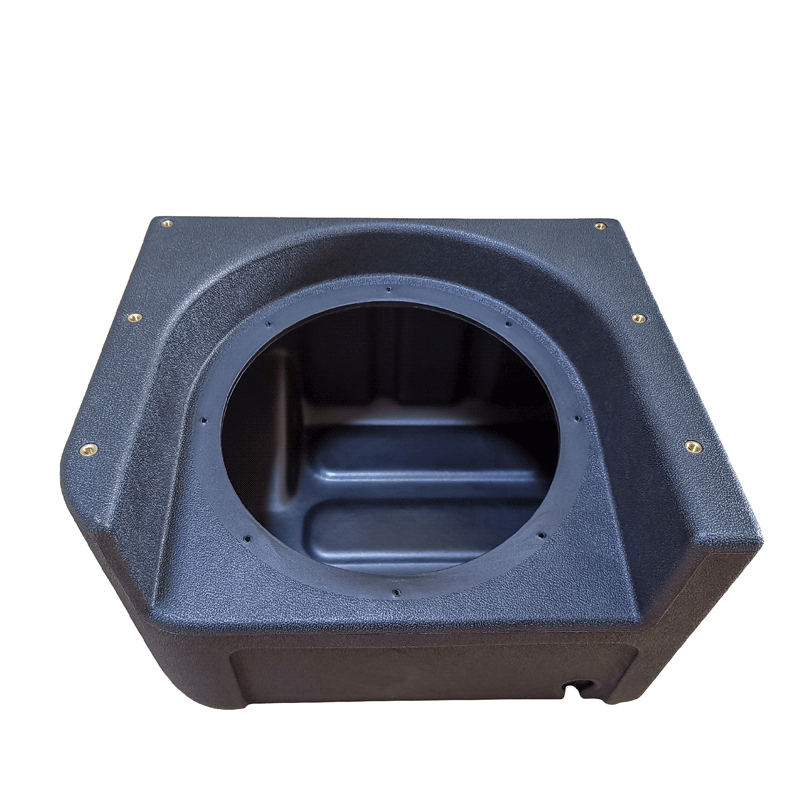

OEM Service Custom Rotomolding of Marine Plastic Speaker Enclosures

High end OEM custom speaker enclosures are made from marine grade HDPE. Roto-mold design with lightweight and durable seamless construction. RoHS compliant & UL rated.

Key features

- Low mould cost, for example, the product of the same specification and size, the cost of roto mould is about 1/3 to 1/4 of the cost of blow moulding and injection mould.

- Design flexibility-from small and intricate to large and complex in any color for visibility or appeal.

- One-piece construction, free of joint, airtight, waterproof

- Molded in insect for mounting the PCBs for cost effectiveness

- 100% Eco friendly polyethylene, food grade, lightweight

- IP67 protection, withstand any extreme weather condition

- High corrosion resistance, resistant to acids and solvents

- Fully UV protection, aging resistant

- Resistant to galvanized currents

What you can expect from our OEM service for a custom built project

- Stable production capacity based on the site of 15000㎡

- An excellent teamwork of more than 500 people

- Strong technical support from Roto Molding Association

- ISO9001 certification, meet the international standards

- Professional engineering team with rich knowledge and experiences

- Provide a total roto molding product solutions with specialized engineering team

- Achieve an efficient development, exquisite appearance, precise size control

- Full service from a concept design to delivery

- 99.9% customer satisfaction

Anything you need from us, be sure to leave us a message by filling the online form, or email us to roto@lightvneus.com, our sales representative will get in touch with you promptly.

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

Related Suggestion

Related Suggestion

Sep 02,2021

Sep 02,2021

Tel

Tel

Email

Email

Address

Address