Light Venus Makes Specific Fixtures for Each Rotomolded Product on Site

Sep 23,2023

Sep 23,2023

Light Venus Makes Specific Fixtures for Each Rotomolded Product on Site

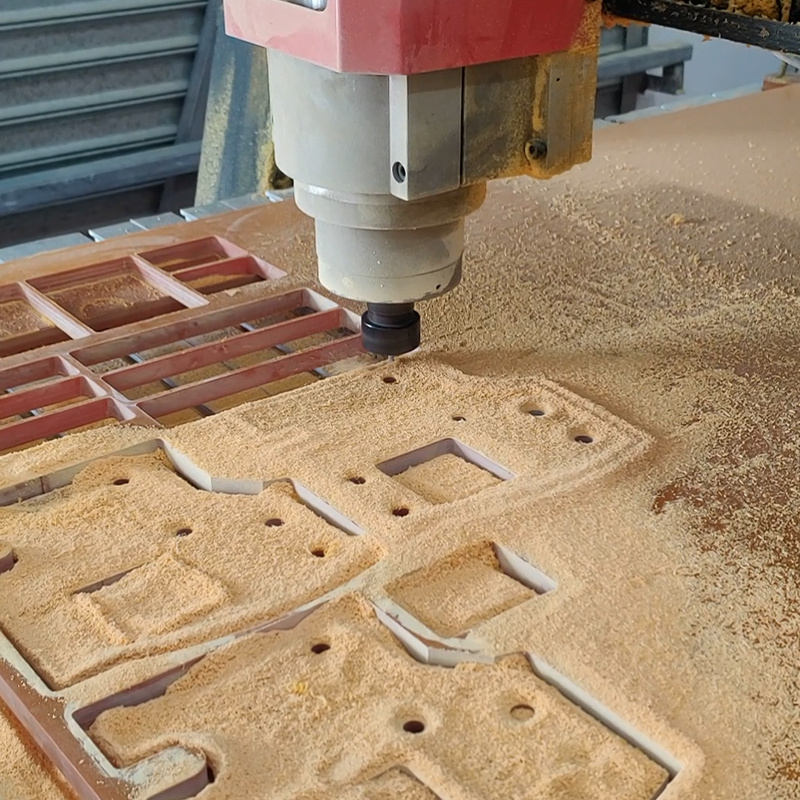

Some rotationally molded parts require finishing operation before shipping out, such as trimming, drilling holes for assembly, cutting out window openings, or deburring. It is especially difficult to trim consistently by hand, so the most efficient and precise way to accomplish this is with CNC Router or Robotic trimming machinery.

CNC Router & Robotic Trimming Features

1. Automation

CNC Router/Robotic trimming automation increase safety, reduces defects, and improves the efficiency of the plastic rotational molding manufacturing process

2. Quality

CNC Router/Robotic trimming is accurate with close tolerance. With highly accurate machinery, once the trimming model is programed and calibrated, CNC Router/Robotic trimming will produce repeatable and precisely trimmed parts

3. Efficiency

CNC Router/Robotic trimming machines are fast, efficient, and can operate continuously and consistently. Human factors, such as fatigue and error are avoided, resulting in an increase in safety, productivity and quality.

4. Flexibility

Design changes are generally easily completed with a programming change. Multiple part configurations and variations can be created from a single formed part by using additional trim programs. Advanced CNC and robotic trimming machines are equipped with integral tool changers, which allow the machine to change finishing tools automatically during a trim cycle. This enables the machine to perform multiple finish operations within one set up with no operator involvement.

Trimming Fixtures

Every rotomolded product that is trimmed by CNC routing and robotic operations needs to be held exactly and securely in place by a fixture. Quality fixtures are essential to the trimming process and key to producing an accurate and repeatable plastic part.

Custom Rotational Molding Service

At Light Venus, we provide value-added custom rotational molding service. The CNC fixtures, or jigs are made specifically for each custom rotational molding project are completed on site. We make sure the production process is accurate and efficient to meet the exact requirement

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home How to Enhance Production Efficiency in Custom Rotational Molding?

How to Enhance Production Efficiency in Custom Rotational Molding?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address