Why Use the Fixtures to Prevent the Rotomolded Products from Shrinkage and Deformation?

Sep 16,2023

Sep 16,2023

Why Use the Fixtures to Prevent the Rotomolded Products from Shrinkage and Deformation?

All materials used in the manufacture of plastic products shrink. The shrinkage is a decrease in the volume of parts during the cooling phase of the plastic. This is quantified by the difference between the dimensions of the part and the dimensions of the molding cavity from which it originates. The differentiated shrinkage is the main cause of various types of warpage.

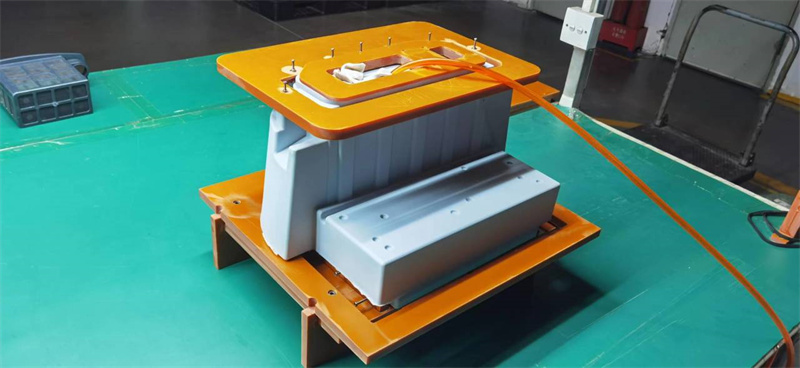

Some rotomolded products such as smart robotic shells and plastic speaker enclosures and other parts require that dimension is strictly correct for assembling other components and parts. While fixtures or jigs are commonly used in the rotational molding process to hold the product in order to prevent the rotomolded products from shrinking and deformation. This is in order to ensure that the product size is accurate after cooling.

At Light Venus, the cooling fixtures are precisely made by CNC machining to make sure the rotomolded products are dimensionally correct. Our rotational molding process is ISO 9001 and ISO 14001 certified. We have all the equipment and expertise necessary to provide an efficient development, create products with exquisite appearance, precise size control and considerable service. Browse our website to learn more about our rotomolded product and custom rotational molding service.

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home Light Venus Makes Specific Fixtures for Each Rotomolded Product on Site

Light Venus Makes Specific Fixtures for Each Rotomolded Product on Site  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address