Mold Trial of Another Custom Rotational Molding Project was Made Successfully

Aug 18,2023

Aug 18,2023

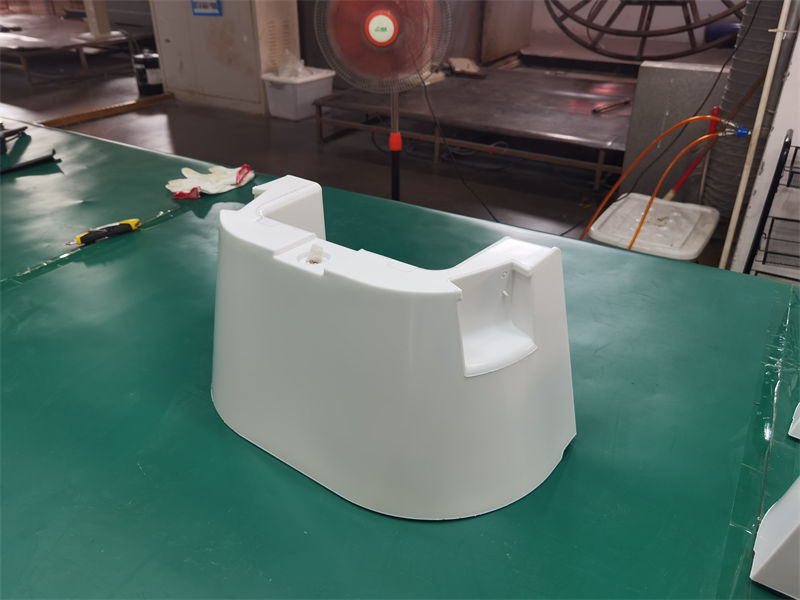

Mold Trial of Another Custom Rotational Molding Project was Made Successfully

We are delightful that mold trial of another custom rotational molding project was made successfully.

Light Venus knows the importance of accuracy. When it comes to custom rotational molding, mold is a key component of rotational molding. Well-designed and made mold and fixture are critical to ensure high-quality rotomolded products and parts with precise dimensions, exquisite appearance and adequate mechanical properties. The mold triad is directly tied to the quality of the tooling used to manufacture it before the mass production begins.

Once the mold fabrication is done, it is essential to do the mold trial prior mass production. This is to verify the feasibility of the mold in the practical production. In case there is problems in mol design and manufacturing process, it needs to analyze it in great detail and modify the mold. Through the mold trial, our engineer team and production team work together to identify the optimal process parameters and requirements, which will be documented and recorded to work out specification sheet and quality assurance checklist for the successful production in rotational molding.

As a professional custom rotational molding manufacturer, we carry the ISO 9001, All the work we do for custom rotational molding project is an integrated systems approach based on ISO 9001 international quality standard. Light Venus ensures these standards through a series of systems set. Throughout the process, we ensure consistent product and tooling development, prototyping, production, on-time delivery and post-production support. Please click here to view our custom rotational molding project. Feel the most welcome to contact us by sending email to roto@lightvenus.com, or chat with us online.

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home Custom Rotational Molding Manufacturing Services of LED Lighting Products

Custom Rotational Molding Manufacturing Services of LED Lighting Products  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address