What are the Features and Applications of Rotomolded Plastic Products?

Aug 03,2023

Aug 03,2023

What are the Features and Applications of Rotomolded Plastic Products?

Rotomolded plastic products have some distinguish features, including durability, strength, and resistance to water, corrosion, impact, weathering, and chemicals. Unlike the wood, steel and other materials, rotomolded plastic products are a lot lighter and easier to install and transport.

Key features

- Hollow one-piece seamless construction, no welds, no joint

- Uniform wall thickness and lightweight

- Resistance to water, corrosion, impact, weathering, and chemicals

- High-quality finishes

- Durability and strength,

- Design flexibility allows for creating large size, intricate products

- Various color options

Applications

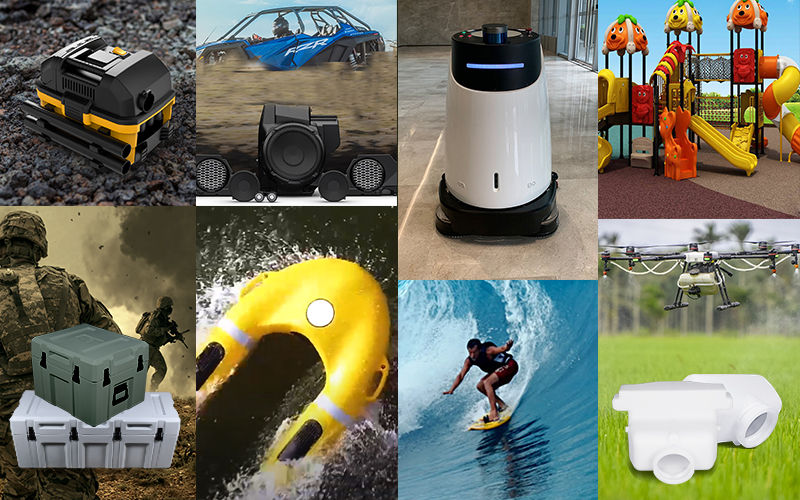

Rotomolded products are widely applied in different industries, including transportation, traffic safety facilities, entertainment, river channel dredging, construction, water treatment, medicine and food, electronics, chemical industry, aquaculture, textile printing and dyeing and other industries. Below are some samples of rotomolded products used commonly in day-to-day life.

Storage tanks

Industrial applications for plastic tanks can include the storage of chemicals, fluids, liquids, fuels, agricultural fertilizers, pesticide. Plastic tanks are also used in the bulk handling of soaps, detergents, and cleaners.

Automotive parts

The durability and seamless features of rotomolded products are ideal parts for the vehicle and automotive industry. Various parts include as air-conditioning elbows, vortex tubes, backrests, armrests, fuel tanks, fenders, door frames and gear lever cover, battery housings, snowmobiles, motorcycle fuel tanks, aircraft fuel tanks, tractor dashboards, truck mudguards, ducting.

Toys and playground equipment

Various plastic toys and playground equipment, such as various dolls, toys, swings, slides, rocking horses, balls.

Marine products

Rotomolded plastic parts are hollow, which has more natural buoyancy rather than solid counterparts, floats, pontoons and buoys, various plastic parts for the water sports industry like boating, surfing, canoeing and kayaking, water rescue equipment smart lifebuoy, and other personal water craft.

Materials handling products

Materials handling products created with rotational molding are sturdy for the purse of storing or shipping the items safely. They have a high load bearing capacity because of their seamless, one-piece construction, such as the bins, food containers, crates, pallets, shipping case, plastic toolbox, packing case and insulated fish and cooler boxes.

Road safety industry

The rotomolded products for road safety industry include bins, road cones, bollards, barrier, traffic dividers and road signs.

Furniture industry

Rotomolded plastic furniture are robustly built for outdoor use. They are dent resistant, chemical resistant, fire retardant and easy to clean. Typical rotomolded furniture includes sofas, chairs, tables, sculptures, flooring, planters.

Industrial parts

Rotomolded d parts are also used in a wide range of industrial, such as the housings and crusts for various smart robot.

Besides these areas, there is a big growth in demand for innovative items including interior and exterior art object, lighting and high-end decorative products.

At Light Venus, we serve a broad range of different industries, including aerospace, industrial, commercial and agriculture. View our products that are crafted by rotational molding process.

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home How to Choose the Right Site for a Rotational Molding Factory?

How to Choose the Right Site for a Rotational Molding Factory?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address