Light Venus Conducts Specific Tests to Ensure Custom Rotomolded Products Quality

From the physical properties to their performance under different conditions, we conduct a series of specific tests to ensure that custom rotomolded products meet the highest standards

Mar 20,2025

Mar 20,2025

How Complex Plastic Speaker Enclosures Are Made with the Rotomolding Process

A step-by-step manufacturing process of creating intricate plastic speaker enclosures made with rotomolding, and its advantages and applications.

Mar 18,2025

Mar 18,2025

How to Optimize Cooling Control in Rotational Molding Process?

Practical tips for managing cooling in the rotational molding process to achieve optimal results, ensuring product quality, dimensional accuracy, and cycle efficiency.

Mar 13,2025

Mar 13,2025

Which Industries Commonly Use Rotomolding Over Injection Molding

Rotomolding is a versatile and cost-effective manufacturing method that offers a range of benefits for producing durable, hollow plastic products for a certain industries.

Mar 11,2025

Mar 11,2025

Light Venus Delivers Custom Complex Plastic Parts Ahead of Schedule

At Light Venus, we have redefined efficiency in rotational molding. By integrating advanced engineering with streamlined processes, we consistently deliver complex plastic components ahead of schedule.

Mar 07,2025

Mar 07,2025

How Does Rotomolding Compare to Injection Molding in Terms of Mold Cost

Rotomolding and injection molding are two distinct manufacturing processes, each with its own cost structure and advantages. The choice between the two processes will depend on the specific requirements of the project, including part size, complexity, production volume, and budget constraints.

Mar 04,2025

Mar 04,2025

Why Choose Rotational Molding to Create Hollow and Complex-Shaped Plastic Products

Rotational molding has unique advantages, including design flexibility, cost-effectiveness, and material versatility, making it the go-to method for producing high-quality rotomolded products.

Feb 27,2025

Feb 27,2025

Light Venus Produces Custom Speaker Enclosures with Rotomolding Technology

By using advanced rotomolding technology, Light Venus offers custom speaker enclosures for professional audio manufacturers and OEM partners seeking tailored solutions that blend durability, design flexibility, and acoustic precision.

Feb 25,2025

Feb 25,2025

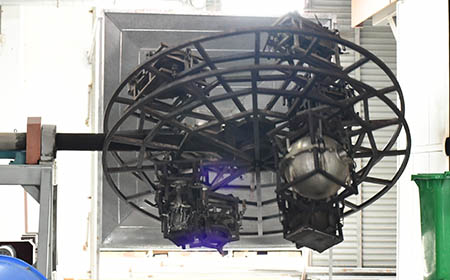

Successful Rotomolding Mold Trial of Smart Lifebuoy Enclosure at Light Venus

Light Venus has successfully concluded the inaugural trial of its rotational molding tooling for a next-generation smart lifebuoy enclosure, custom-developed through strategic collaboration with a leading OEM partner.

Feb 20,2025

Feb 20,2025

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address