What are the Factors Affecting Load-bearing Capacity of Rotomolded Products

Several factors influence the load-bearing capacity of rotomolded products Understanding the factors that influence load-bearing capacity is crucial for rotational molding manufacturers to refine the rotational molding process and improve the product’s load-bearing capabilities.

Jun 17,2024

Jun 17,2024

How to Assure the Durability of Rotomolded Products at Light Venus

To assure the durability of rotomolded products at Light Venus, a comprehensive approach is implemented, encompassing material selection, design optimization, process control, quality assurance, surface treatment, using post-processing techniques and preventive maintenance.

Jun 05,2024

Jun 05,2024

Why Do We Need Vent Holes in Rotational Molding Molds

In rotational molding process, vent holes allow for the escape of air and gases, facilitate even heating and cooling, and contribute to overall productivity by reducing cycle times and minimizing defects.

Jun 03,2024

Jun 03,2024

How to Optimize the Demolding Stage in Rotational Molding Process

Several key strategies can be implemented in order to optimize the demolding process and achieve high-quality rotational molding products with minimal defects and maximum efficiency

May 31,2024

May 31,2024

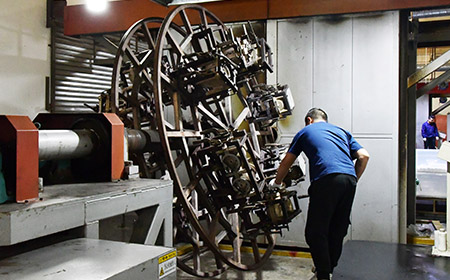

Light Venus Expands Production Capacity with the Addition of Two Brand New Rotational Molding Machines

Light Venus is pleased to announce the acquisition of two state-of-the-art rotational molding machines. These new machines will significantly increase the production capacity, enabling us to meet the growing demand for high-quality roto moulding plastic products.

May 30,2024

May 30,2024

The Demolding Procedure in Rotational Molding Process

Understanding and mastering the demolding process will contribute to the success and efficiency of rotational molding operations in various industries.

May 29,2024

May 29,2024

What Types of Rotational Molding Products are Particularly Made with Aluminum Molds

Aluminum molds demonstrate particular advantages in the creation of a diverse range of rotational molding products, spanning from large industrial components to custom-designed consumer goods.

May 28,2024

May 28,2024

Surface Finishing is important to Enhance Overall Quality of Rotomolded Products

Cleaning, texturing, polishing, coating, painting, anodizing, and decorating are some of surface finishing techniques to enhance the aesthetics and functionality of rotomolded products.

May 25,2024

May 25,2024

What are the Common Methods to Test Color Difference for Rotational Molding Products

Spectrophotometers, colorimeters, and visual inspections are common methods used for color difference testing in rotational molding process. Each method has its advantages and limitations, and the choice of method depends on factors such as the required accuracy, cost, and time constraints.

May 24,2024

May 24,2024

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address