What is Robomolding?

Robomolding is an innovation of rotational molding technology. This technique uses manufacturing practices and robotics to precisely deliver heat to molds, leading to differences in part tolerances, material choices, and the complexity of designs that can be achieved.

Jul 27,2022

Jul 27,2022

Light Venus is full force in the production of custom rotomolded polyethylene lamps

UV-resistant polyethylene lamps manufactured at low production cost by means of rotational molding are shatterproof, waterproof and weatherproof for reliable indoor and outdoor use. The material is sustainable and 100% recyclable.

Jul 25,2022

Jul 25,2022

What Kinds of Lighting Products are Made with Rotational Molding?

A vast array of innovative products with intricate contours and geometric shape are manufactured with rotational molding because of its ability to specifically produce hollow products with almost no limits on size and shape, while the tooling cost is relatively low.

Jul 18,2022

Jul 18,2022

Custom Rotational Molding Plastic Parts are under Production for an OEM customer

Light Venus was chosen by an OEM company to manufacture their plastic parts for their robotic equipment. Their team approached to Light Venus with the requirement of durability, low cost, precise size for the assembly.

Jul 15,2022

Jul 15,2022

OEM Custom Rotational Molding Service for Food Containers

Rotational molding creates extremely strong, long lasting, durable, food container with one-piece, seamless construction, featuring resistance to chemicals and the elements. Can be custom built to meet the rigorous standards of FDA

Jul 14,2022

Jul 14,2022

Custom Rotational Molding Plastic Housings and Other Parts for Robotic Equipment

Strong and durable robotic equipment housings other parts are manufactured by rotational molding technology in a wide variety of shapes, sizes, textures, and colors with features such as low production cost, undercuts, multiple walls, and molded-in hardware and graphics.

Jul 08,2022

Jul 08,2022

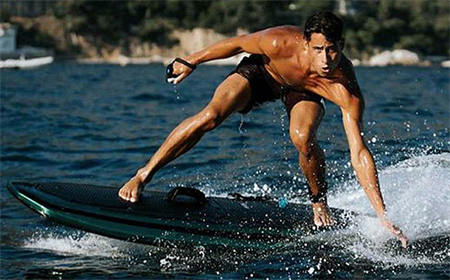

Why Choose Rotomolding to Make Electric Surfboard Shell?

Thanks to the rugged characteristic of roto molded rotationally polyethylene and the natural buoyancy that accompanies most sealed rotomolded products, the water sports essentials like the kayaks, boat, canoe and are manufactured by rotational molding, including the popular electric surfboard.

Jul 05,2022

Jul 05,2022

What Is An Electric Surfboard?

Electric surfboards are specially designed boards powered by lithium-ion batteries that allow riders to glide across any water body at high speeds. They are equipped with an electric jet-propulsion system activated by wireless handheld remote control and don't rely solely on the energy of the waves to gain speed.

Jun 22,2022

Jun 22,2022

What Kinds of Marine Products Are Made With Rotomolding?

Due to the rugged and robust nature of roto molded polyethylene and the incredible buoyancy that accompanies airtight and watertight rotomolded products, makes the rotomolding process is a great fit for a variety of products for marine application.

Jun 21,2022

Jun 21,2022

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address