Quality Custom Rotational Molding Service of Agriculture Drone Water Tank at Light Venus

Rotational molding is ideal for drone water tanks. This is because this process provides a number of advantages over other molding method, such as low tooling costs, joint-free, strong air tightness, light weight, impact resistance, anti- corrosion, rust resistance.

Aug 29,2022

Aug 29,2022

What Types of Polyethylene are Commonly Used for Rotational Molding?

Polyethylene is available in a variety of grades and formulations. Based on density property, there are four main categories of polyethylene thermoplastic material used for rotational molding. The selection of the type of polyethylene depends on the design and intended function of the rotomolded products.

Aug 25,2022

Aug 25,2022

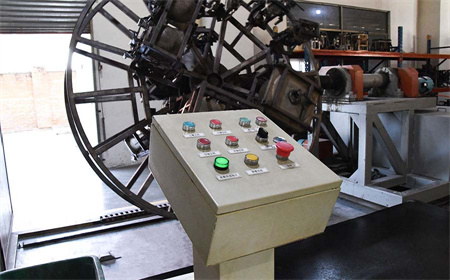

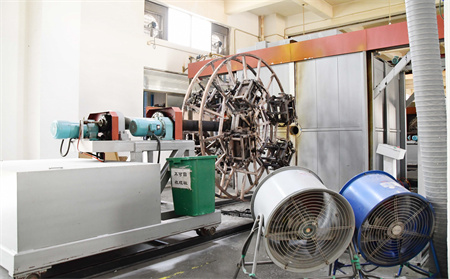

Light Venus Provides Custom Precise Rotational Molding Tooling Making Service

With over 500 employees and over 20-year experience in custom rotational molding products, we have the skill and knowledge to make any unique and complicated tooling for rotational molding process. Light Venus tooling program can save both money and time by developing molds in-house as an integral part of the total project.

Aug 21,2022

Aug 21,2022

What types of Tooling are Used in Rotational Molding?

Three different types of tooling are commonly used in rotational molding process. They are Cast Aluminum, CNC machined aluminum, electroformed & fabricated sheet Metal. Each type of tooling has its own benefits and product design parameters.

Aug 16,2022

Aug 16,2022

Custom Rotomolding Plastic Speaker Enclosure with Assembly Services

At Light Venus, our comprehensive custom rotomolding solutions include assembly services that add value and reduce cost. No matter how simple or complex of the requirements, our engineering staff will work closely with your team to develop the assembly process that best fits the specific requirements.

Aug 13,2022

Aug 13,2022

Our Rotational Molding Factory Has Passed Annual BSCI Audit

As a custom rotational molding factory with BSCI certificate, Light Venus always puts sustainable trade at the heart of our operation. We have an excellent team of dedicated people and well-established facility, serving OEMs customers by producing quality custom rotomolded products with precise size and exquisite appearance.

Aug 10,2022

Aug 10,2022

Rotational Molding Brings Innovation to Lighting Products

Rotational molding brings innovation to the lighting products. This technology offers designers the great design freedom to create the lighting products with both functionality and aesthetic impact, adding stylish and decorative elements to the indoor or outdoor space.

Aug 09,2022

Aug 09,2022

Light Venus Delivered Custom Rotational Molding Polyethylene Lamps on Time

Light Venus is more than a custom rotational molding factory. We also provide electric assembly and final testing services. This means that we are able to offer our customers fast production and on-time delivery.

Aug 04,2022

Aug 04,2022

Light Venus Offers Value Added Custom Rotational Molding Services

Light Venus specializes in custom rotational molding products for commercial and industrial sectors with a full range of assembly and testing services that adds value to rotomolded products, saving both time and money by eliminating secondary operations.

Aug 02,2022

Aug 02,2022

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address