Draft Angles Design Consideration for Rotomolded Products

When designing draft angles for rotomolded products, factors such as material considerations, product shape and geometry, mold design, and transition areas must be carefully considered to ensure a successful demolding process, reduce production time and increase efficiency

Mar 12,2024

Mar 12,2024  30

30

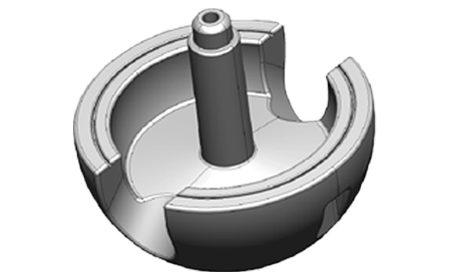

Basic Requirements for Rotational Molding Mold Design and Production

The design and production of rotational molding mold require careful attention to several key factors to ensure the production of high-quality rotomolded products.

Mar 11,2024

Mar 11,2024  32

32

Light Venus Expanded Production Capacities with Additional Rotational Molding Machines

Light Venus increased its production capacities by setting up more rotational molding machines, which help meet the growing demand and ensure timely delivery to our customers.

Mar 08,2024

Mar 08,2024  15

15

How to Design Wall Thickness Range for Rotomolded Products

The determination of the optimal wall thickness range in rotomolded products is contingent upon a multitude of factors, encompassing the intrinsic properties of the materials used, the intended application of the product, and a careful consideration of the manufacturing process.

Mar 06,2024

Mar 06,2024  85

85

What Methods are Commonly Used to Heat the Rotational Molding Machines

Among the rotational molding machine heating methods, gas-fired, electric, infrared, and hot air heating techniques are commonly used. Each method has its advantages and applications.

Mar 05,2024

Mar 05,2024  82

82

Steps for Structural Inspections in Rotational Molding Process

Conducting structural inspections within the rotational molding process entails a comprehensive suite of procedures, including visual examination, precise dimensional measurements, sample sectioning, microscopic analysis, mechanical testing, pressure tests, as well as evaluations for ESCR.

Mar 04,2024

Mar 04,2024  9

9

Analysis and Solutions for Uneven Wall Thickness of Rotomolded Products

Various factors can contribute to uneven wall thickness in rotomolded products, including inconsistent material distribution,flawed mold design, improper processing parameters, and compromised integrity of the mold material.

Mar 02,2024

Mar 02,2024  24

24

Why Rotomolded Products Need Rounded Corners

Rotomolded products with rounded corners offers several advantages. It ensures uniform wall thickness, improves stress distribution, prevents voids and defects, enhances aesthetics, facilitates demolding, and prevents warping.

Mar 01,2024

Mar 01,2024  19

19

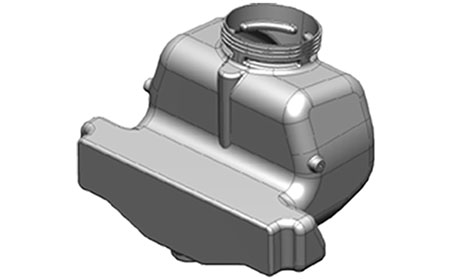

Techniques and Considerations for Demolding in Rotational Molding Process

Demolding is the process of removing the solidified plastic product from the mold after the rotomolding cycle is complete. It requires careful attention to ensure that the product is not damaged or deformed

Feb 29,2024

Feb 29,2024  59

59

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address