General Design Guidelines for Corner Radii in Rotomolded Products

Useful design guidelines for incorporating corner radii into rotational molded products effectively. Considerations include appropriate corner radius, product application, uniform wall thickness, aesthetic considerations, mold design and construction, transition areas, material selection.

Mar 21,2024

Mar 21,2024

The importance of Wall Thickness Uniformity in Rotational Molding

Maintaining uniform wall thickness is paramount in the rotational molding process. It is essential for guaranteeing structural integrity, enhancing product durability, optimizing overall performance, and preserving aesthetic appeal.

Mar 20,2024

Mar 20,2024

How to Design the Threads for Rotomolded Products?

Threads design on rotomolded products is a complex process that involves multiple aspects, including material, mold design, and manufacturing techniques. The design and production of threads require consideration of the product's requirements, the type and size of the threads, and the characteristics of the rotational molding process.

Mar 19,2024

Mar 19,2024

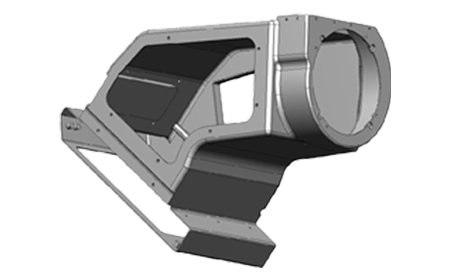

Rotomolded Plastic Cases Offer Rugged and Durable Solutions for Industrial Applications

Crafted through the rotational molding technique, plastic cases feature a seamless construction, excellent impact resistance, and remarkable durability. They provide a robust and reliable solution for industrial applications that demand strong, reliable, and versatile packaging.

Mar 17,2024

Mar 17,2024

What are the Key Factors Affecting the Lifespan of Rotomolded Products

The key factors that affect the lifespan of rotomolded products include raw material quality, production technology, product design, surface treatment, environment conditional and maintenance, etc.

Mar 16,2024

Mar 16,2024

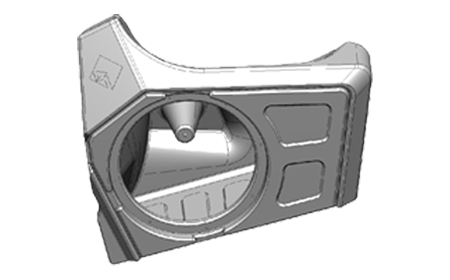

How to Design the Holes for Rotomolded Products

Holes or vents in rotomolded products can be designed as either outward-projecting through-holes, blind holes, or as inward-recessed through-holes or blind holes.

Mar 15,2024

Mar 15,2024

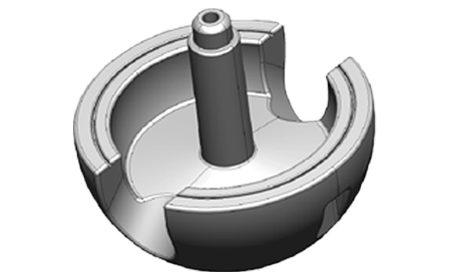

Types of Rotational Molding Molds

In the rotational molding industry, common methods for creating molds include aluminum casting molds, sheet-metal molds, and molds that are computerized numerically controlled (CNC).

Mar 14,2024

Mar 14,2024

Draft Angles Design Consideration for Rotomolded Products

When designing draft angles for rotomolded products, factors such as material considerations, product shape and geometry, mold design, and transition areas must be carefully considered to ensure a successful demolding process, reduce production time and increase efficiency

Mar 12,2024

Mar 12,2024

Basic Requirements for Rotational Molding Mold Design and Production

The design and production of rotational molding mold require careful attention to several key factors to ensure the production of high-quality rotomolded products.

Mar 11,2024

Mar 11,2024

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address