What are the Comprehensive Steps for Dimension Verification of Rotomolding Molds at Light Venus

The process of dimension verification for rotomolding molds at Light Venus is comprehensive and meticulous, ensuring the accuracy and reliability of the mold to craft high-quality rotomolded parts.

Oct 14,2024

Oct 14,2024

Light Venus Offers an Array of Finishing Services for Custom Rotomolded Products

Whether it's drilling, cutting, special openings or adding custom graphics, Light Venus offers a comprehensive range of finishing services for custom rotomolded products. Our expertise ensures that each product meets the highest standards of quality and aesthetic appeal.

Sep 25,2024

Sep 25,2024

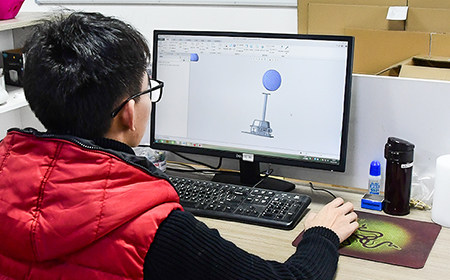

What are the Drawing Review Process for Rotational Molding Tooling at Light Venus

The streamlined drawing review process for rotational molding tooling at Light Venus is a comprehensive and collaborative effort aimed at producing high-quality tooling that meets the specific needs of each project.

Sep 18,2024

Sep 18,2024

Light Venus Launched Internal Quality Training Program on Rotational Molding Process

Light Venus recently launched an internal quality training program focused on the rotational molding process. We strive to maintain the highest standards of rotational molding product quality and efficiency in our operations.

Sep 03,2024

Sep 03,2024

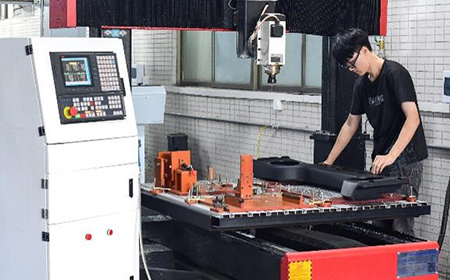

How to Achieve Precise size Control in Roto Moulding Process at Light Venus

At Light Venus, we utilize a series of techniques to ensure the dimensional accuracy of rotomolded products throughout the roto moulding process.

Aug 24,2024

Aug 24,2024

Light Venus is Honored with Best Enterprise Award by Rotomoulding Professional Committee of CPPIA

As a dedicated custom rotational molding manufacturer, Light Venus is honored to have been recognized with the prestigious Best Enterprise Award by the Rotomoulding Professional Committee of the China Plastics Processing Industry Association (CPPIA).

Aug 22,2024

Aug 22,2024

How to Assure the Durability of Rotomolded Products at Light Venus

To assure the durability of rotomolded products at Light Venus, a comprehensive approach is implemented, encompassing material selection, design optimization, process control, quality assurance, surface treatment, using post-processing techniques and preventive maintenance.

Jun 05,2024

Jun 05,2024

Light Venus Expands Production Capacity with the Addition of Two Brand New Rotational Molding Machines

Light Venus is pleased to announce the acquisition of two state-of-the-art rotational molding machines. These new machines will significantly increase the production capacity, enabling us to meet the growing demand for high-quality roto moulding plastic products.

May 30,2024

May 30,2024

Light Venus has Successfully Fulfilled a Custom Order for Rotomolded Plastic Water Barriers

As a dedicated custom rotational molding factory, Light Venus has consistently established itself as a trusted manufacturer in the industry, providing innovative and durable plastic solutions with a focus on delivering high-quality products that meet the specific needs of clients

May 15,2024

May 15,2024

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address