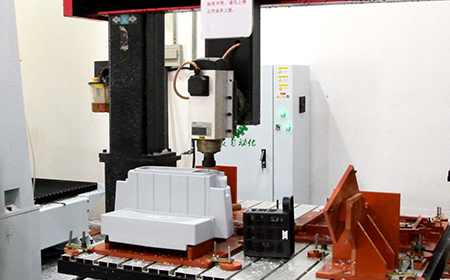

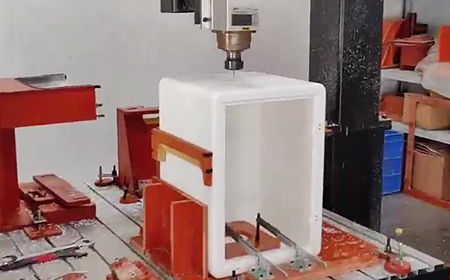

Light Venus has Invested Advanced CNC Equipment to Assure the Precision of Rotomolded Products

Light Venus, has substantially invested in cutting-edge technology, which encompasses sophisticated Computer Numerical Control (CNC) machinery, to guarantee the accuracy and precision of rotomolded products during trimming processes.

May 11,2024

May 11,2024

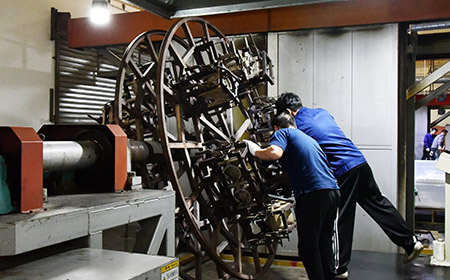

Light Venus Annually Produces Millions of Polyethylene Plastic Ball Lamp Shade with Roto Molding

With well-established roto molding factory and a team of dedicated professionals, light Venus produces millions of custom plastic ball lamp shades annually. These premium plastic spherical lampshades are engineered for durability, functionality, and aesthetic appeal.

May 06,2024

May 06,2024

Light Venus Offers Custom Precision Rotational Molding for Various Industrial Parts

Light Venus, a custom roto molding manufacturer, has been utilizing the rotational molding process to produce various industrial plastic parts for various applications. including the automotive, construction, agricultural, transportation and other industries.

May 05,2024

May 05,2024

How to Design High-Strength Rotational Molding Products

Comprehensive guidelines for designing rotational molded products of exceptional strength, encompassing crucial aspects such as material selection, part architecture, mold fabrication, and processing parameters.

Apr 28,2024

Apr 28,2024

How to Make Production Plans for Rotational Molding Process?

Creating a production plan in rotational molding encompasses several critical aspects, which include evaluating production capacity, defining the product mix, organizing the production schedule, managing inventory, overseeing and regulating the production process, and implementing continuous improvement

Apr 13,2024

Apr 13,2024

Light Venus Enhances Rotomolded Products with Precision CNC trimming for Perfect Fit and Finish

Light Venus is delighted to provide our OEM/ODM customers with value-added CNC trimming services to enhance rotomolded products for perfect fit and finish.

Apr 08,2024

Apr 08,2024

Light Venus Produces Millions of Rotomolded Plastic Lampshade Annually

Crafted from durable and lightweight polyethylene, rotomolded plastic lampshades are ideal for a variety of lighting applications, offering practicality and cost-effectiveness.

Apr 07,2024

Apr 07,2024

Light Venus Implements Mold Trial for Custom Rotomolded Products

By conducting mold trials, Light Venus refines its product design, optimizes production processes, and guarantees the anticipated quality and functionality of the products.

Apr 02,2024

Apr 02,2024

Light Venus Offers Custom Roto Molding Service for Diverse Industries

From playful plastic toys to intricate aerospace components, Light Venus specializes in providing custom roto molding services for a wide array of industries.Our dedication to innovation, quality, and customer satisfaction allows us to excel in turning concepts into robust, functional, and high-quality rotomolded products that meet the unique needs of various sectors.

Mar 28,2024

Mar 28,2024

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address