How do we ensure quality of rotational molding products at Light Venus?

Light Venus makes our commitment to providing high-quality, consistent products and services to our customers. Custom rotational molding products are manufactured strictly through an effective quality management system to ensure customers’ satisfaction.

Apr 19,2022

Apr 19,2022

Why do We Use High Density Polyethylene for Plastic Lamp shade?

Highly density polyethylene is a perfect combination of durability, good malleability, and environmental friendliness, making it a ideal material choice for the wide application of plastic lamp shade.

Mar 27,2022

Mar 27,2022

Why do We Use Polyethylene for Rotomoulded Products at Light Venus?

Polyethylene meets almost any requirement, whether that is for impact resistance, temperature stability, chemical resistance, colour, UV stability and durability. The distinctive characteristics have made them the most widely used plastic for rotational molding.

Mar 25,2022

Mar 25,2022

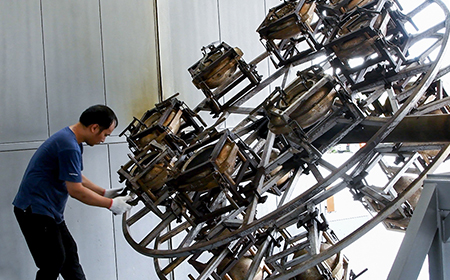

Light Venus just added a brand new rotomoulding machinery

Light Venus is a reliable manufacturing partner to OEM from all over the world, producing a variety of rotomoulded products. We added a brand new rotomoulding machinery to increase the capacity for the growing demands of our customers.

Mar 14,2022

Mar 14,2022

Won the Honor of Rotomoulding Professional Committee of China Plastics Processing Industry Association

Light Venus was honored again as a committee member of Rotomoulding Professional Committee of China Plastics Processing Industry Association. We will continue make our commitment to our core values to customers to create higher quality rotomoulded products.

Feb 27,2022

Feb 27,2022

Why Use Rotomolding to Create Plastic Lampshades?

Made of polyethylene resin as a one-piece product by rotomolding process, plastic lampshades have high quality standard. Materials and colors are highly resistant to UV and chemical elements for the durability. Shapes, size, design can be very flexible for a wide range of application, while the tooling cost is relatively inexpensive.

Feb 25,2022

Feb 25,2022

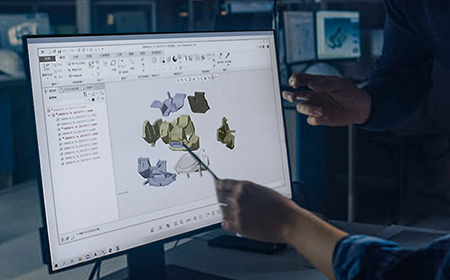

What is the Rotational Molding Design Process?

The rotational molding process offers highly flexibility in design and manufacturing, yet it accordingly requires lots of design consideration in every aspect of shape, structure, appearance, function and manufacturing process.

Jan 08,2022

Jan 08,2022

What are the Basics of Roto Moulding Process?

Roto moulding, also known as rotational molding, is a plastics molding technology which is ideal for making hollow products. Different from most other plastics process, it is a forming technology without pressure Any shape and size can achieved through this process. Due to the one-piece molding process, the products have high tensile strength and uniform wall thickness, whilst the roto moulding are relatively inexpensive and the production runs in a cost effective way

Nov 02,2021

Nov 02,2021

What are the Advantages of Rotational Molding?

Rotational molding is the most distinct plastic shaping processes. Compared with extrusion and injection molding, the process has distinctive advantages use to create hollow plastic products in a vast variety of shape and size with uniform wall thickness with high quality performance. The process is also extremely versatile for a variety of different surface finishes and textures. The products can add inserts to avoid the cost of 2nd operation. The tooling cos is relatively lower and little material is wasted in production.

Nov 02,2021

Nov 02,2021

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address