What are the Criteria Used to Inspect the Appearance of Rotomolded Products?

The appearance of rotomolded products significantly impacts their aesthetics and functionality. Therefore, it is crucial to inspect the appearance rigorously to ensure they meet the desired specifications and customer expectations.

Feb 15,2024

Feb 15,2024

How to Optimize the Rotational Molding Process

Optimizing rotational molding process involves various aspects, including optimizing mold design and construction, selecting the right material, controlling process parameters, implementing quality control measures, and continuous improvement.

Feb 14,2024

Feb 14,2024

What are the Main Parameters for Setting Up Rotomolding Process?

Setting up the rotomolding process with the appropriate parameters is essential for achieving high-quality products. The key parameters include the oven temperature, rotation speed and pattern, cooling time, material drying, and mold design.

Feb 11,2024

Feb 11,2024

What are the Common Methods for Inspection and Testing in Rotational Molding?

Ensuring the quality and integrity of rotomolded products requires the use of various inspection and testing methods, including visual inspection, dimensional inspection, material testing, leak testing, performance testing, and environmental testing.

Feb 09,2024

Feb 09,2024

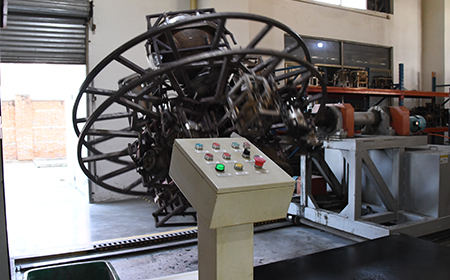

Why Rotational Molding Becomes a Significant Plastic Manufacturing Process?

Rotational molding has become an integral part of modern industrial plastic manufacturing thanks to its versatility, material flexibility, ability to produce stress-free and seamless products, cost-effectiveness, environmental advantages, and assurance of quality and consistency.

Feb 08,2024

Feb 08,2024

What is Rotational Molding Tooling Design Process at Light Venus?

The design process of rotational molding tooling involves several critical steps, including conceptualization, 3D modeling, mold design, consideration of constraints, prototype testing, final mold production, and quality control.

Feb 07,2024

Feb 07,2024

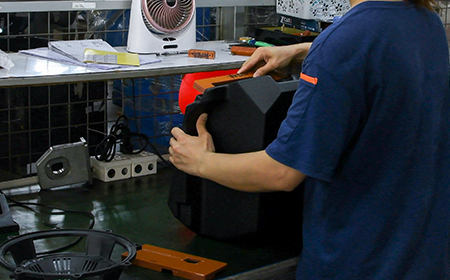

What are the Key Characteristics of Rotomolded Products

The key characteristics of rotomolded products include hollow and seamless products, stress-free structures, complex geometries and customization options, uniform wall thickness, high impact resistance, chemical resistance, and weather resistance.

Feb 05,2024

Feb 05,2024

How to Test the Surface Hardness in Rotational Molding Process?

An overview of surface hardness testing in rotational molding process and the guidance on how to test surface hardness effectively.

Feb 01,2024

Feb 01,2024

How To Control Air Flow in Rotomolding Process?

Proper air flow management in rotomolding process is essential for achieving uniform heating, preventing deformation, and ensuring the high-quality of the final rotomolded products

Jan 31,2024

Jan 31,2024

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address