What Type of Post-Processing Techniques Commonly Used for Rotomolded Products

Trimming and cutting, deburring and finishing, painting and coating, assembly and fitting, and quality control and inspection are some of the common post-processing techniques used in rotomolded products.

Apr 09,2024

Apr 09,2024

How to Incorporate Inserts in Rotomolded Products

General guide on how to incorporate inserts in rotomolded products to enhance both their functional capabilities and aesthetic appeal.

Apr 05,2024

Apr 05,2024

Roto Molding Process is a Popular Manufacturing Technique Across Multiple Industries

The roto molding process is a popular manufacturing technique used in various industries for its ability to create durable, lightweight, and seamless plastic products

Apr 03,2024

Apr 03,2024

Rotational Molding Opens Up New Avenues for Creating Smart Robotics Housings

With its cost-effectiveness, customization, lightweight design, and durability, rotational molding is poised to become a preferred manufacturing method for smart robotics housings

Apr 01,2024

Apr 01,2024

What are the Kiss-off Ribs and Discrete Ribs in Rotational Molding

Kiss-off and discrete ribs are two common types of strengthening elements used in rotomolded products. These ribs help distribute mechanical stresses more evenly throughout the product, improving its ability to withstand loads and impacts.

Mar 30,2024

Mar 30,2024

How to Incorporate Threads into Rotomolded Products

Various techniques are used to incorporate threads into rotomolded items, which not only enhance the functionality of the product but also ensure a secure and precise fit

Mar 29,2024

Mar 29,2024

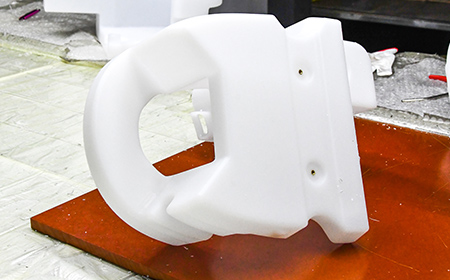

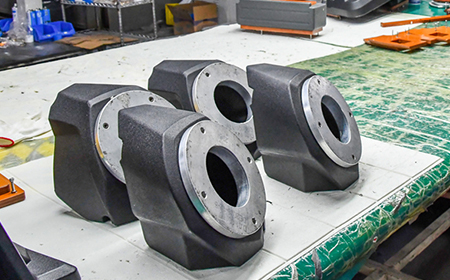

What are the Main Materials Used in Rotational Molding Molds Fabrication?

The main materials used in rotational molding mold include aluminum, steel, stainless steel, and fiberglass. Each material has its own unique properties and advantages, making them suitable for different applications and production requirements.

Mar 26,2024

Mar 26,2024

Reinforcing Ribs Design Guidelines for Rotomolded Products

Reinforcing ribs are used to enhance the structural integrity and durability of rotomolded products. When designing ribs for rotational molded products, several factors must be taken into account to make sure that the ribs are effectively integrated into the product design.

Mar 25,2024

Mar 25,2024

General Design Guidelines for Corner Radii in Rotomolded Products

Useful design guidelines for incorporating corner radii into rotational molded products effectively. Considerations include appropriate corner radius, product application, uniform wall thickness, aesthetic considerations, mold design and construction, transition areas, material selection.

Mar 21,2024

Mar 21,2024

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address