Applications of Rotomolded Plastic Speaker Enclosures

Rotomolded plastic speaker enclosures provide a versatile and durable solution suitable for an extensive array of applications, ranging from outdoor entertainment to vehicle.

Apr 24,2024

Apr 24,2024

Light Venus Adds Value to Custom Rotomolded Products with In-house Foaming Capabilities

Light Venus's integration of in-house foaming capabilities has significantly added value to their custom rotomolded products. This innovative move not only improves product quality and performance but also offers cost advantages for customers.

Apr 23,2024

Apr 23,2024

How to Ensure the Proper Materials Storage in Rotational Molding Process

Guidelines for ensuring the correct storage of plastic materials in rotational molding process to minimize the risk of material degradation and maintain the desired properties of the rotational molded parts.

Apr 22,2024

Apr 22,2024

How to Determine Material Quality in Rotational Molding Process

Determining material quality in the rotational molding process involves a combination of visual inspection, material certification, melt flow index measurement, material drying, sample testing, and proper storage conditions.

Apr 19,2024

Apr 19,2024

Strength and Hardness Standards in Rotational Molding

Strength and hardness are essential properties for rotational molded products, affecting their durability, wear resistance, and overall performance.

Apr 17,2024

Apr 17,2024

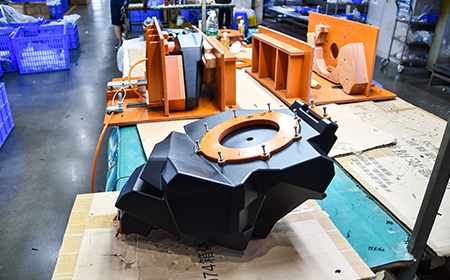

The Unique Features of Rotomolded Plastic Speaker Enclosures

Rotomolded plastic speaker enclosures provide a combination of superior sound quality, robust durability, and a lightweight design, coupled with customization options, weatherproofing capabilities, and eco-friendliness

Apr 16,2024

Apr 16,2024

How to Judge Density Precision in the Rotational Molding Process

By optimizing process parameters sensibly, regulating heating temperature and pressure, choosing appropriate materials, and performing real-product testing, the density accuracy in rotational molding can be enhanced, thereby satisfying the quality demands of the product.

Apr 14,2024

Apr 14,2024

Methods for Inspecting the Uniformity of Wall Thickness in Rotomolded Products

Various methods, such as visual inspection, measuring tapes and calipers, non-destructive testing (NDT) methods, X-ray radiography, CT scanning, and simulation and modeling, can be used to assess wall thickness uniformity of rotomolded products.

Apr 12,2024

Apr 12,2024

How to Decide Whether Rotational Molding is Suitable for a Plastic Product

When considering the use of rotational molding for a plastic product, it is essential to take into account several key factors: the product's size, the complexity of its shape, the structure of the mold, the type of material to be used, as well as the desired cost and quality outcomes.

Apr 11,2024

Apr 11,2024

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address