What are the Advantages of Sheet Metal Molds Used in the Rotational Molding Process

Sheet metal molds offer a combination of durability, precision, cost-effectiveness, versatility, faster cycle times, and compatibility with automation that make them an ideal choice for use in the rotational molding process.

May 13,2024

May 13,2024

Essential Information for Designing and Manufacturing the Roto Mold Tooling

in order to successfully design and manufacture the roto mold tooling,. there are some key pieces of information that should be taken into account during the tooling-making process.

May 12,2024

May 12,2024

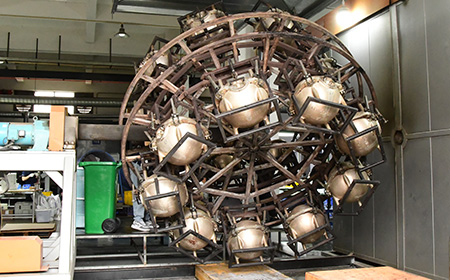

Rotational Molding is An Ideal Manufacturing Process for Molding Complex Shape Plastic Lamps

As the demand for innovative and aesthetically pleasing lighting solutions continues to grow, rotational molding will play a crucial role in shaping the future of lamp design and manufacturing.

May 03,2024

May 03,2024

What are the Performance Characteristics of Linear Low-density Polyethylene

Linear low-density polyethylene (LLDPE) is a versatile material with excellent performance characteristic, such as good chemical resistance, thermal stability, impact resistance, flexibility, and low density make it a popular choice for packaging, construction, agriculture, and many other applications.

May 02,2024

May 02,2024

The Key Features of Low-Density Polyethylene and High-Density Polyethylene

LDPE and HDPE have different performance characteristics that make them suitable for different applications. LDPE is more flexible, durable, and transparent, while HDPE is stronger, stiffer, and more chemical-resistant.

May 01,2024

May 01,2024

Why Polyethylene Becomes the Main Material for Rotational Molding?

Polyethylene becomes the main material choice in the rotational molding industry thanks to its versatility, cost-effectiveness, easy processing, chemical stability, low weight, and impact resistance.

Apr 30,2024

Apr 30,2024

Considerations in Designing Tolerances for Rotational Molding Products

Designing tolerances for rotational molding products requires careful consideration of various factors, including mold design, material selection, wall thickness, draft angles, design for assembly, dimensional stability, and tolerance stack-up.

Apr 29,2024

Apr 29,2024

What Type of Rotomolded Products are Added with Foam Filling?

Foam filling is a common feature added to rotomolded products to enhance their performance, safety, and comfort. Whether it's keeping coolers insulated, making storage containers quieter, providing additional padding in kayaks, increasing visibility in safety equipment, or adding comfort to benches and chairs, foam filling is a versatile and useful feature in rotomolded products.

Apr 26,2024

Apr 26,2024

The Advantages of Foam Filling in Plastic Rotomolded Products

Foam filling offers numerous advantages to plastic rotomolded products, enhancing their insulation, strength, weight reduction, noise dampening, impact absorption, and customization.

Apr 25,2024

Apr 25,2024

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address