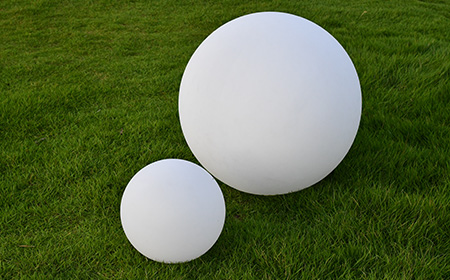

Can Rotational Molding Process Produce High-quality Plastic Lampshade?

From its ability to produce uniform wall thicknesses and seamless finishes to its versatility in creating complex shapes, rotational molding is an innovative process in the world of plastic lampshade design and manufacturing.

Oct 08,2024

Oct 08,2024

What are the Advantages of Roto Moulding in Manufacturing Plastic Speaker Enclosure

Roto moulding is a preferred choice for manufacturing plastic speaker enclosures due to its ability to create complex shapes, ensure uniform wall thickness, and offer cost-effective, durable, and customizable solutions.

Aug 31,2024

Aug 31,2024

Rotomolding Offers Distinct Advantages for Manufacturing Parts Used in Cleaning Robot

Rotomolding offers distinct advantages for manufacturing parts used in cleaning robots. This process is well-suited for producing lightweight, durable, and functional parts that meet the demanding requirements of cleaning robots in various environments.

Aug 26,2024

Aug 26,2024

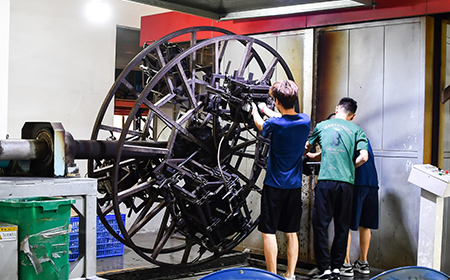

How to Prevent the Rotomolded Products from Deformation in Rotational Molding Process

Preventing deformation in rotomolded products during the rotational molding process is a critical aspect that requires meticulous attention to several key factors, including material selection, mold design, process parameters, equipment maintenance, and post-processing techniques.

Aug 20,2024

Aug 20,2024

Manual Deburring Process for Rotomolded Products

By meticulously inspecting and deburring their products, rotational molding manufacturers can mitigate potential issues associated with burrs, thereby elevating customer satisfaction and product performance.

Jul 02,2024

Jul 02,2024

What are the Types of Deburring Process for Rotomolded Products

There are various deburring processes available for rotomolded products, each with its advantages and limitations. The choice of deburring process depends on factors such as the complexity of the part, production volume, and material type.

Jun 30,2024

Jun 30,2024

What the Effective Ways to Evaluate the Load-bearing Capacity of Rotational Molding Products

The determination of the load-bearing capacity in rotational molding products necessitates an integration of theoretical computations, material evaluations, and empirical observations.

Jun 18,2024

Jun 18,2024

What are the Factors Affecting Load-bearing Capacity of Rotomolded Products

Several factors influence the load-bearing capacity of rotomolded products Understanding the factors that influence load-bearing capacity is crucial for rotational molding manufacturers to refine the rotational molding process and improve the product’s load-bearing capabilities.

Jun 17,2024

Jun 17,2024

Why Do We Need Vent Holes in Rotational Molding Molds

In rotational molding process, vent holes allow for the escape of air and gases, facilitate even heating and cooling, and contribute to overall productivity by reducing cycle times and minimizing defects.

Jun 03,2024

Jun 03,2024

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address